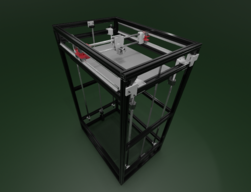

KeePrint Monster

Discussion in '3D printers' started by checkeredBug, Apr 21, 2019.

KeePrint Monster

Discussion in '3D printers' started by checkeredBug, Apr 21, 2019.

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.