Bright Box Cartesian Printer

Discussion in '3D printers' started by Darren Ditto, Mar 28, 2015.

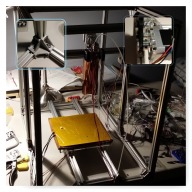

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Discussion in '3D printers' started by Darren Ditto, Mar 28, 2015.

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint