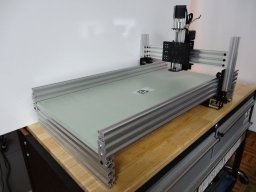

Routy CNC Router (V-Slot Belt & Pinion)

Discussion in 'CNC Mills/Routers' started by Mark Carew, Nov 11, 2013.

ROUTY CNC Router (V-Slot Belt & Pinion)

Discussion in 'CNC Mills/Routers' started by Mark Carew, Nov 11, 2013.

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

Page 17 of 21

Page 17 of 21