LCD Based SLA Resin Printer

Discussion in '3D printers' started by evilc66, May 3, 2016.

LCD Based SLA Resin Printer

Discussion in '3D printers' started by evilc66, May 3, 2016.

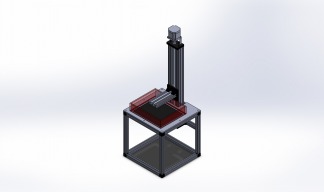

SLA resin printer based on a gen3/4 iPad Retina display. The design intent is to create a printer with the highest resolution possible with a lower cost of entry compared to DLP projector based SLA printers.

Page 1 of 15

Page 1 of 15