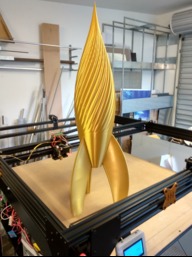

Large 'Double H-Bot' using 2040 Openbuilds v-slot

Discussion in '3D printers' started by Peter Stoneham, Mar 17, 2019.

Large 'Double H-Bot' using Openbuilds 2040 v-slot

Discussion in '3D printers' started by Peter Stoneham, Mar 17, 2019.

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.