CoreXY 3D Printer

Discussion in '3D printers' started by CoreCube3D, Jan 4, 2019.

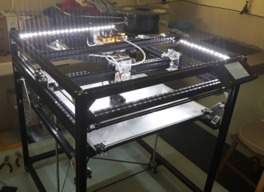

CoreCube3D - A CoreXY 3D Printer

Discussion in '3D printers' started by CoreCube3D, Jan 4, 2019.

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.