CNC-inator3000

Discussion in '3D printers' started by Nicademus, Feb 13, 2018.

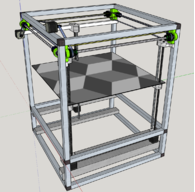

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Discussion in '3D printers' started by Nicademus, Feb 13, 2018.

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.