CNC Greenland Paddle Carver build

Discussion in 'CNC Mills/Routers' started by Andre Cooke, Jan 15, 2018.

CNC Greenland Paddle Carver build

Discussion in 'CNC Mills/Routers' started by Andre Cooke, Jan 15, 2018.

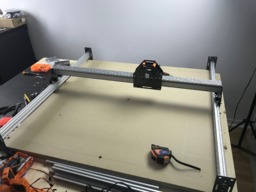

CNC mill for carving / milling Greenland Paddles