A simple XY laser engraver/cutter

Discussion in 'Laser Cutters' started by HPB, Nov 2, 2016.

A simple XY laser engraver/cutter

Discussion in 'Laser Cutters' started by HPB, Nov 2, 2016.

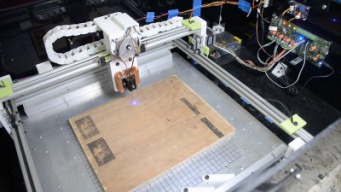

A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed.

Page 1 of 3

Page 1 of 3