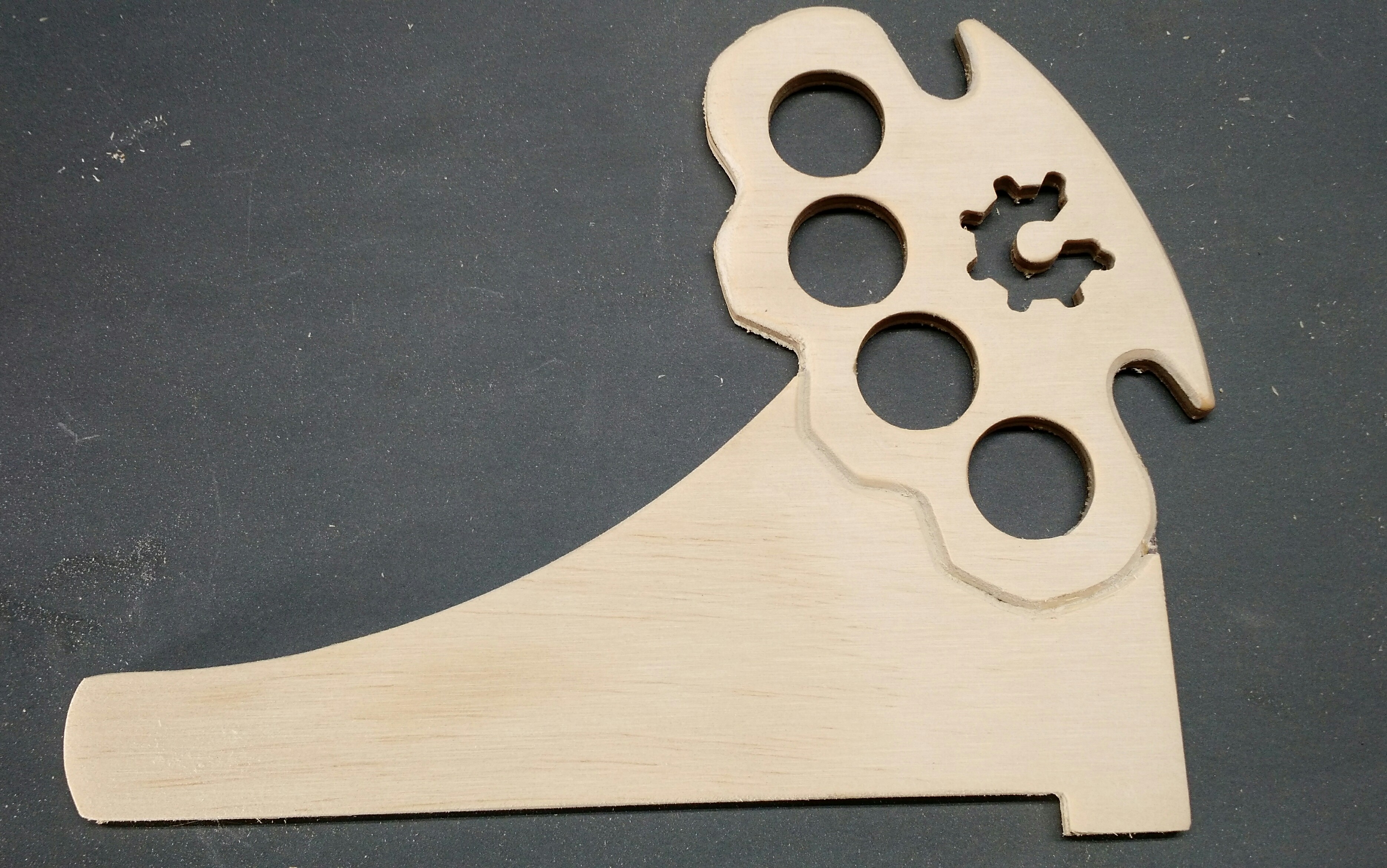

I was in dire need of a new set of saw push sticks for my table saw so I don't have to get my fingers close to the saw blade, but i wanted something that looked a bit tough and edgy so i headed of to google image search for a vector image of some brass knuckles. after a quick trace of the the vector image I had a working DXF file to start designing around. I took a pair of calipers and measured my fingers and scaled the vectors to allow for a comfortable allowance that allowed a nice fit in my hand. the remaining vectors were drawn in free form until I was satisfied with the look of it

- Software:

- vectric , chillipeppr

- Machine Time:

- ~10 min

- Bit or Laser Size:

- 1/8" 90 degree v-bit , 1/8" 2 flute carbide endmills

- Materials:

- Plywood

I have attached the DXF File for you to make your own, there is is a nexted vector of the outline of the brass knuckles which uses a vbit first to chamfer the edge which helps cut back on the sanding required at the end and to define the shape of the brass knuckles in the push stick (note a ball nose endmill or small flat endmill can be substituted if you like). next a 1/8" flat endmill was used to cut out the finger holes first followed by the outside profile with tabs added to hold the pieces in place ( 1mm tall x 4mm wide tabs). after the cycle was complete a utility knife was used to cut the tabs and a hand file to knock them down flush. 220 grit sandpaper to knock any burrs and edges off.

-

Dismiss NoticeThis site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.

User Comments

Sort Comments By