I think a dust boot is a good rite-of-passage for beginning CNC people. This is my second dust boot for the DW611. First one was similar to the others that clamp onto the router barrel (including the one sold in the OB Store). This was disappointing in multiple ways but the two biggest issues: it puts the vacuum hose quite a way from the router bit and it is big so it will hang over the the front of the spoil board and not (or poorly) collect dust in that situation. So, my requirements when I sat down to design this:

- Software:

- SketchUCAM, GRBL-Panel

- Machine Time:

- all in, about 1 hr

- Bit or Laser Size:

- 1/8" endmill, 1/2" 90 deg Vbit

- Feeds & Speeds:

- 1000 mm/Min, 30000RPM (no real thought here, still experimenting)

multipass at 1.6mm per pass. (probably can increase this)

- Materials:

- wood: 1/2" Baltic Birch, 1/4" Baltic Birch

HW: Rockler 1/4" Cam Lever, 2.5" dust port, screws & washers

Other: dust bristle strip, glue

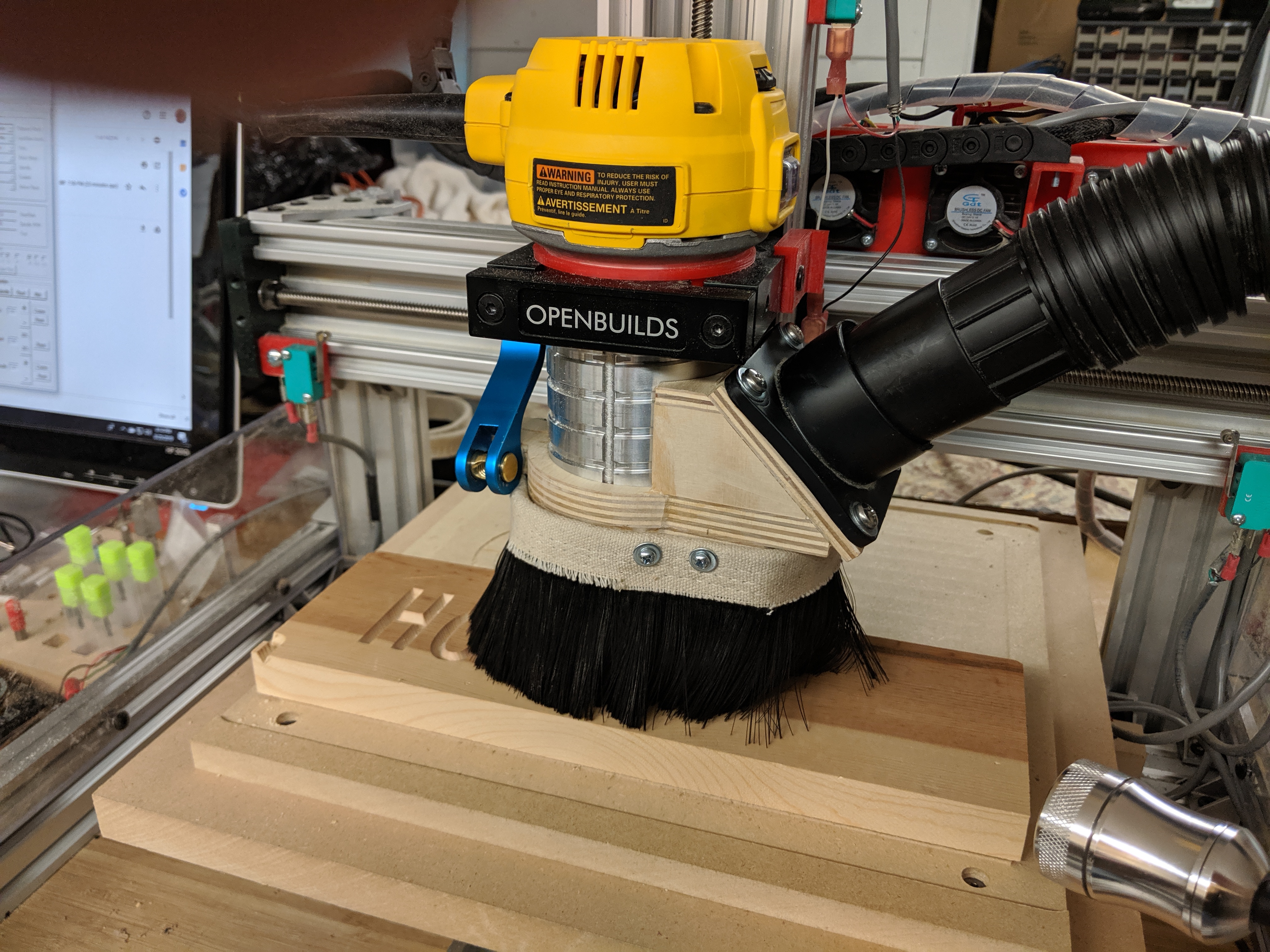

In the last photo you can see the results of the first test. The work area was completely dust free with a tiny bit on the workpiece. Very happy with the results. My biggest concern, that the 1/4" BB wouldn't be strong enough, turned out to be groundless. Some small tweaks if I build another:

- Small footprint

- Vacuum hose opening close to the bit

- Vacuum hose entering at 45 degrees to minimize hose stress

- Fast on/off for tool changes

- increase the length of the cam hole bracket by 5mm to allow better clearance of the spindle mount

- pocket the base 1/2" piece for the vertical triangles to allow positive alignment when gluing.

- bevel the inside of the dust port hole on the port mounting plate (reduce air resistance)

- increase the multipass cut size to decrease machine time.

I have plans to make this out of polycarbonate for better bit visibility though I'm not sure it will be all that good given the skirt. Just have to try it.

Photos, in order:

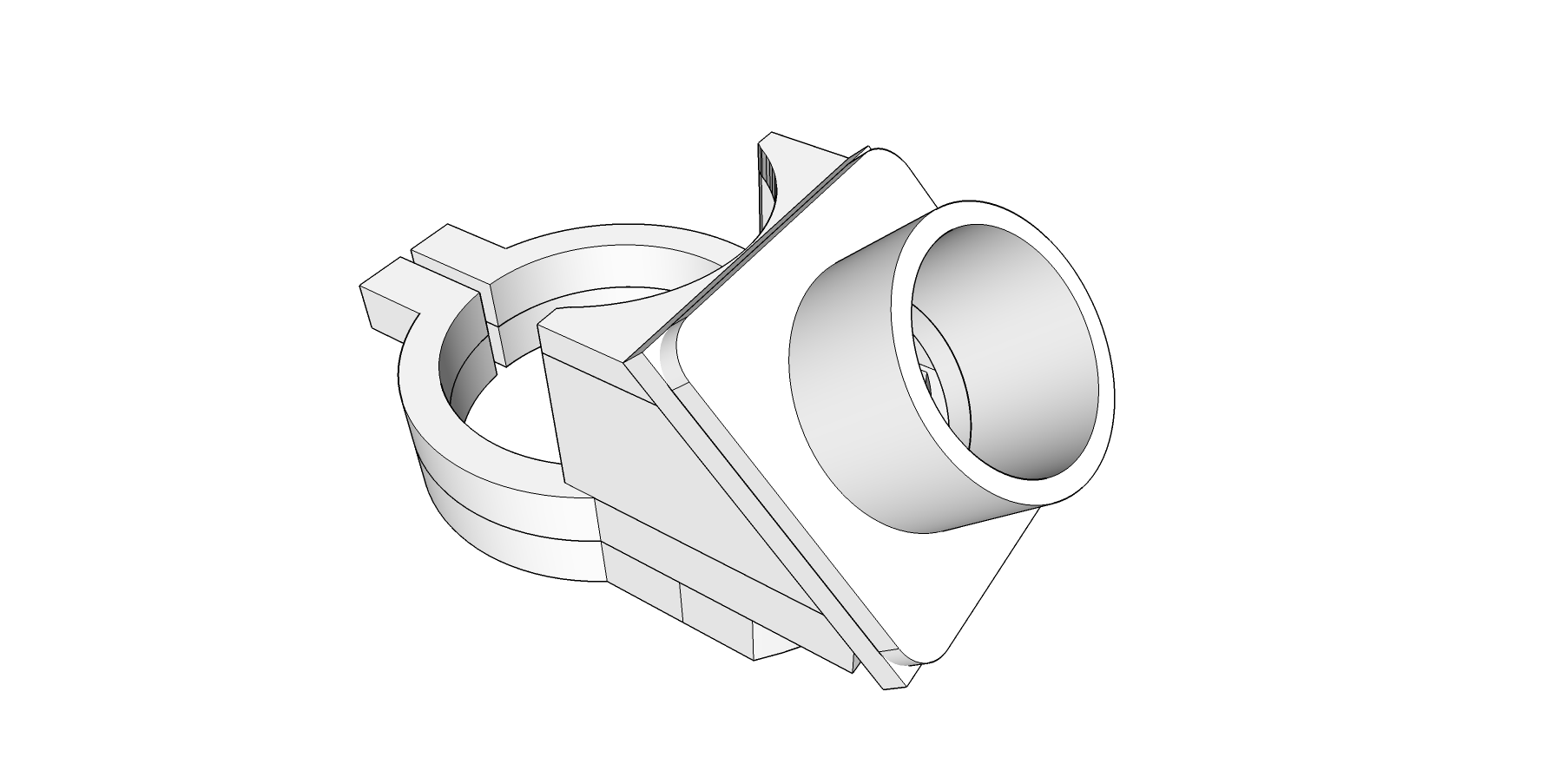

- 3D view

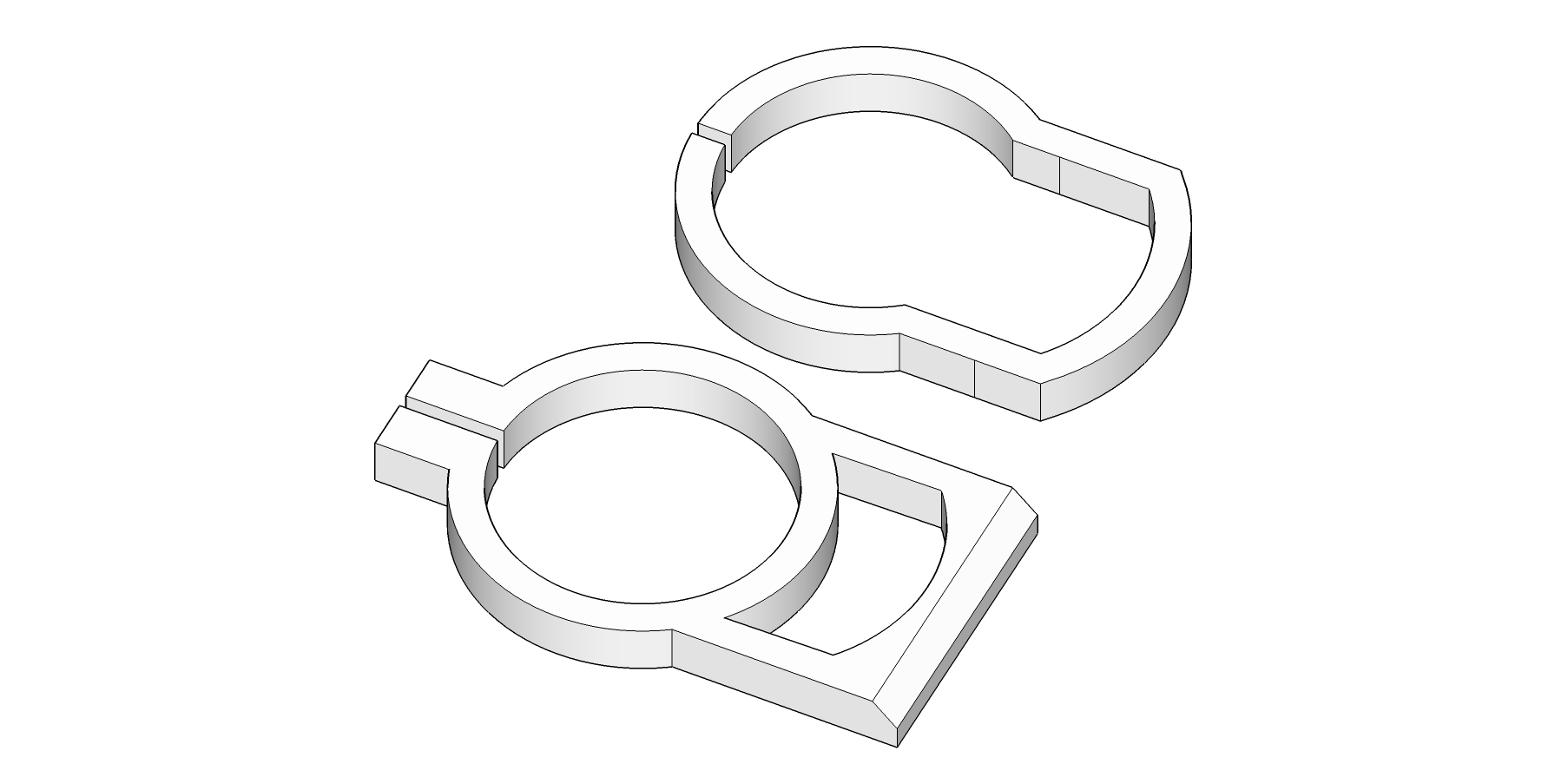

- 12mm BB Parts - smaller one holds the skirt in place

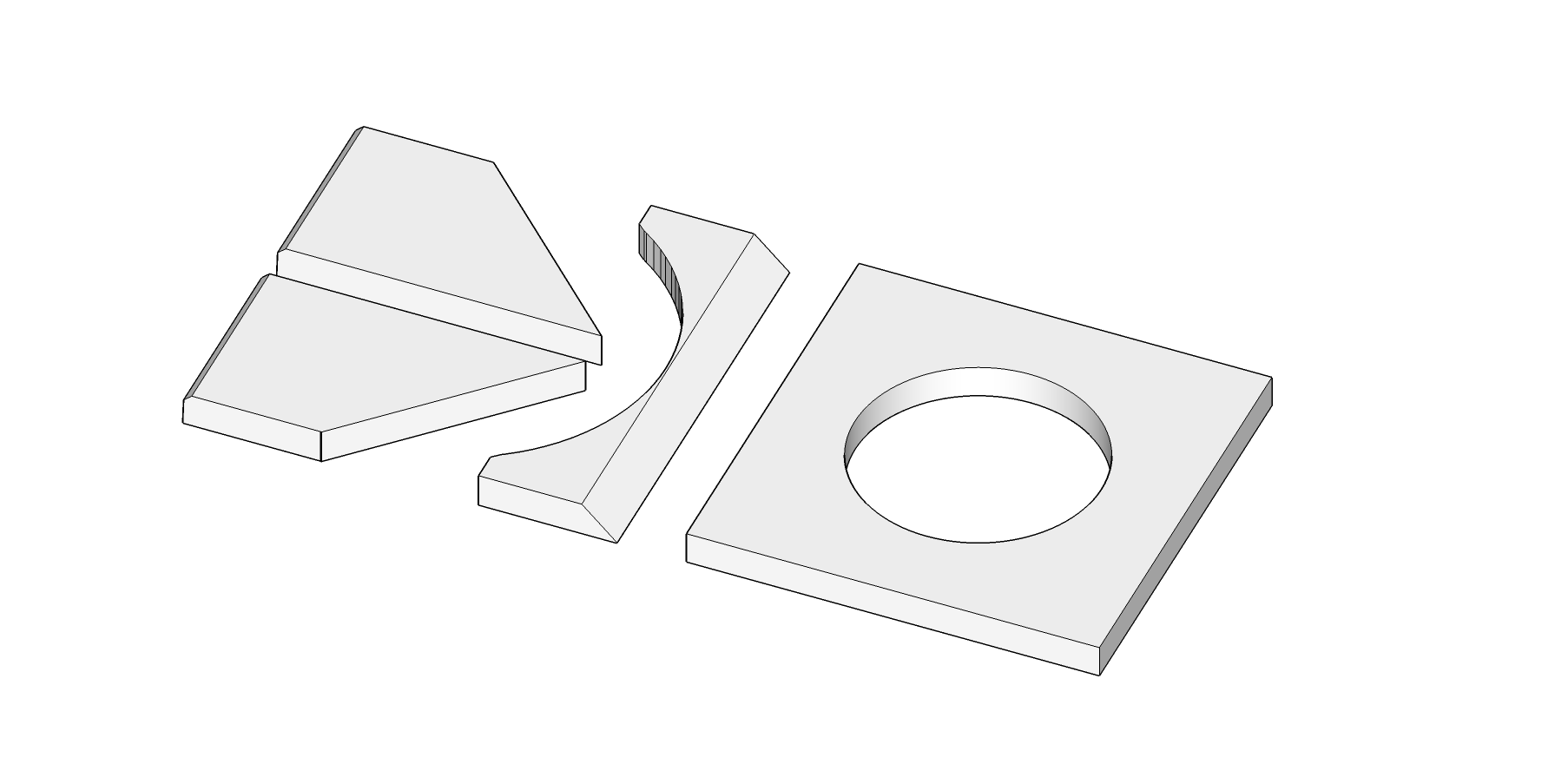

- 6mm BB Parts - Risers, spindle collar and dust port mount

- Front Right view showing hose attachment

- Front Left view showing cam clamp

- Front View showing completed test run. Nothing was done other than move the Y forward to show the results.

-

Dismiss NoticeThis site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.

User Comments

Sort Comments By