- Machine Type:

- Laser / Plasma

- Software:

- LightBurn, Fusion 360

- Machine Time:

- less than 5 min

- Bit or Laser Size:

- Very small like .1mm or less

- Feeds & Speeds:

- 200mm/min 100% Power On the Co2 Laser ACRO build

- Materials:

- Acrylic cast sheet, Steel, Mic Booms

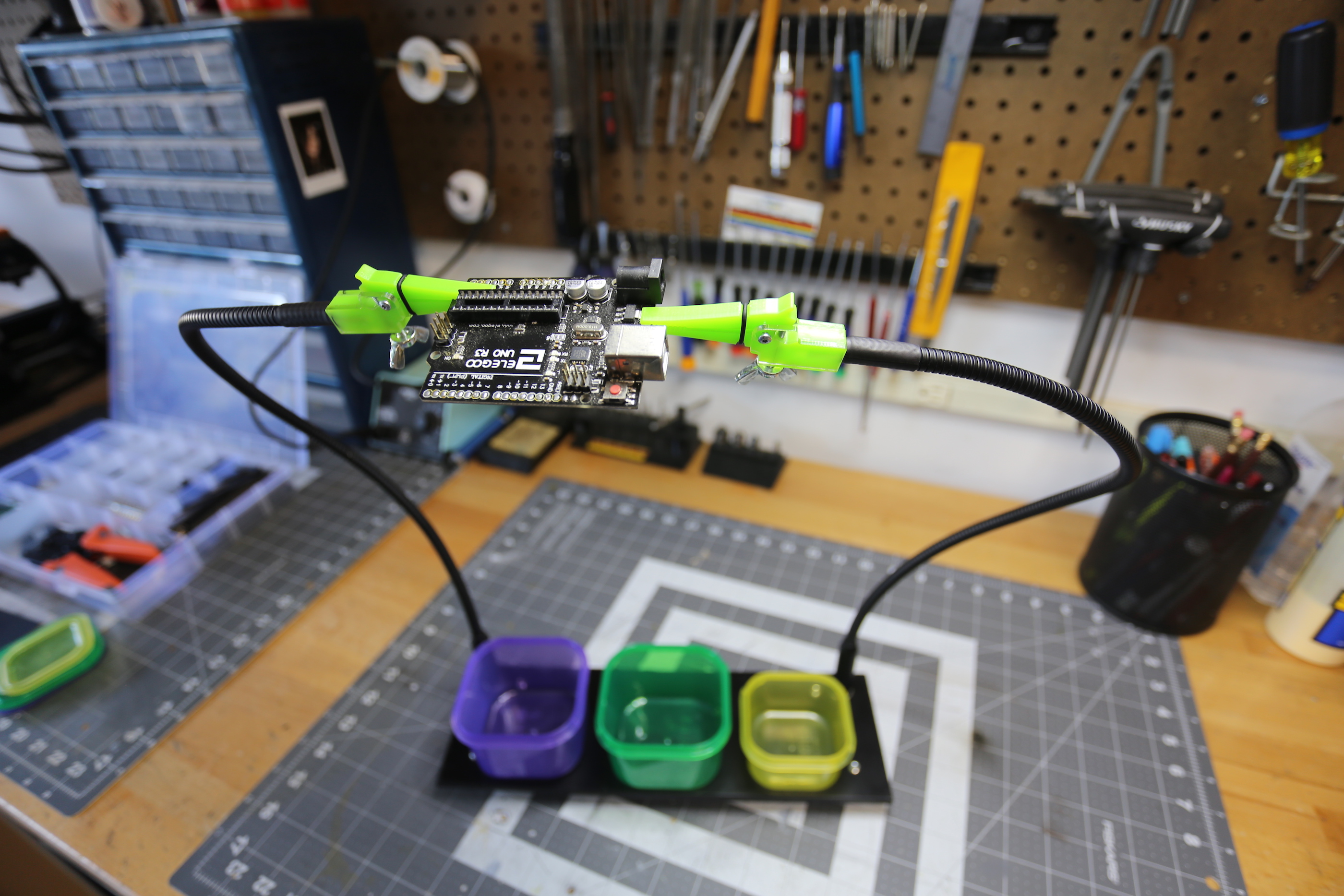

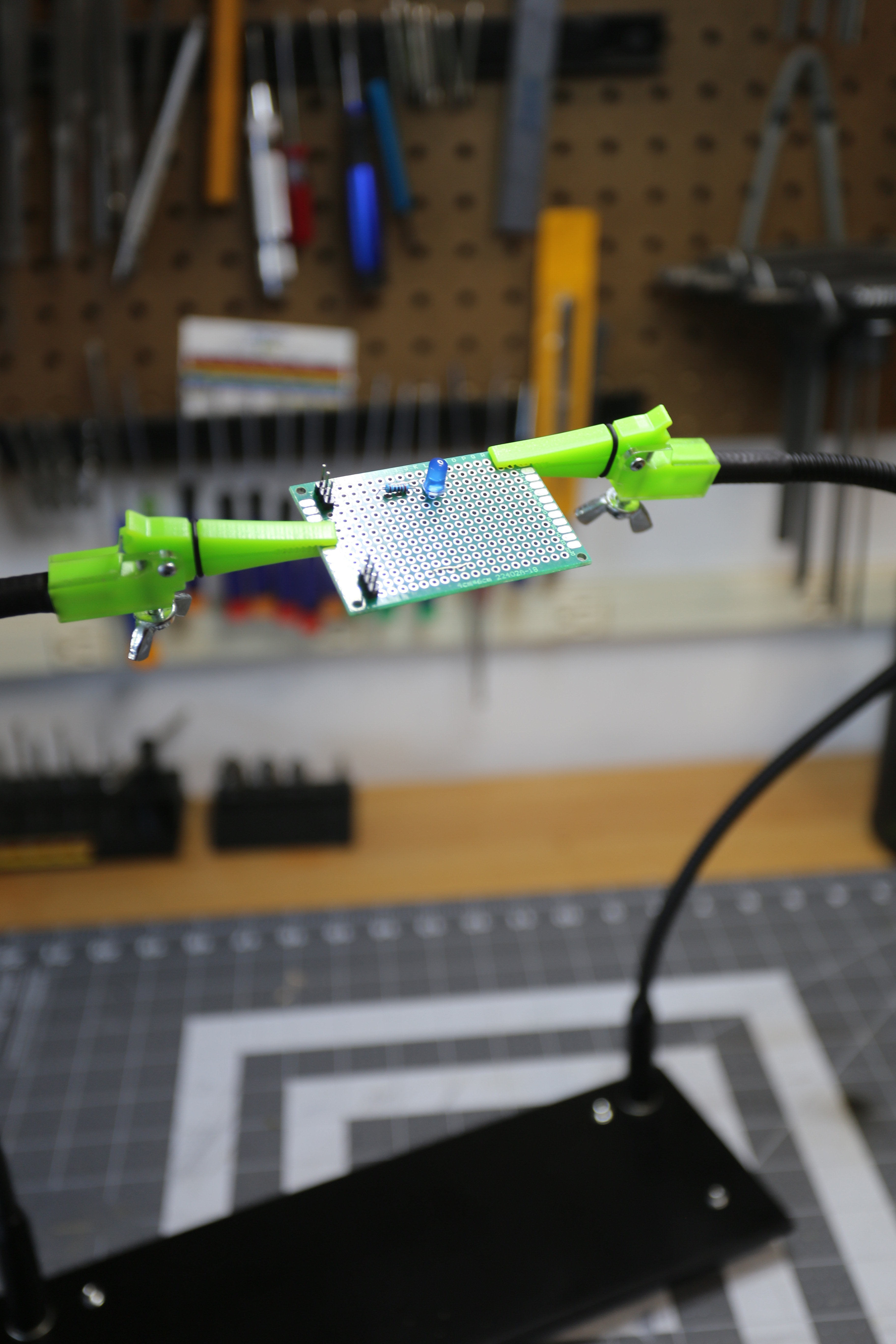

So I'm getting into building my own circuits. I've been etching the boards on the laser cutter then using acid to melt away the copper, which is Awesome (More to come on this!) I didn't like the old board holder I made just using regular gator clips which sometimes didn't hold very well. also the arms were way to springy. No better way to spend a day than making a new tool! (maybe drinking on a tropical island..) so I had some left over bendy mics from work, the things tellers use to talk in the drive through. I had a couple ideas how to make the scissor action on the CNC but I wanted to challenge myself to make a gator clip on the laser cutting machine. Which was a lot harder to come up with then I thought, kinda stared at the screen more than I normally do. I wanted something that could be delicate or really squeeze down on something. Please Check out the video and consider subscribing. Thanks!

Follow me on instagram @jakeslabnc

My lovely wife took the photos. @theladywithacanon

-

Dismiss NoticeThis site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.

User Comments

Sort Comments By