IndieLC

Discussion in '3D printers' started by Indieflow, Apr 11, 2015.

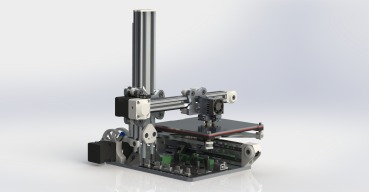

Indie i2

Discussion in '3D printers' started by Indieflow, Apr 11, 2015.

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Page 2 of 10

Page 2 of 10