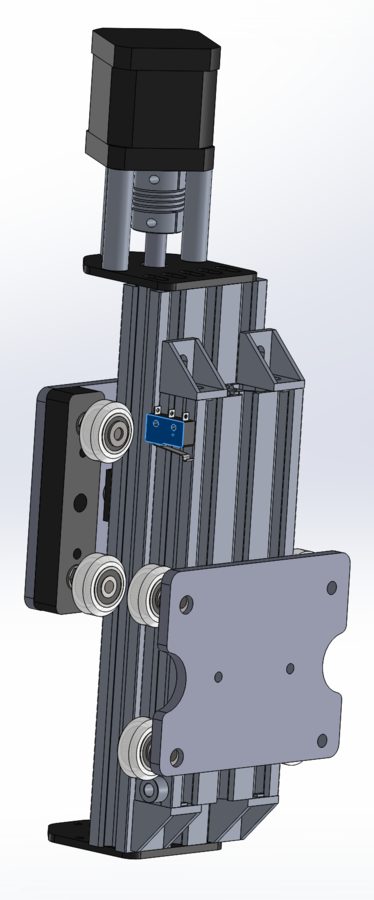

I will explain here how works the Z floating head that i use on my 2 plasma cutting table .

For more information , you can find full builds here :

.It's really easy to modify your good OX CNC to a plasma cutter , you just have to modify a little bit your Z axis .

What is the purpose of a floating head ? :

Just like on a classic cnc , you have to know your Z zero and it is the goal of the floating head .

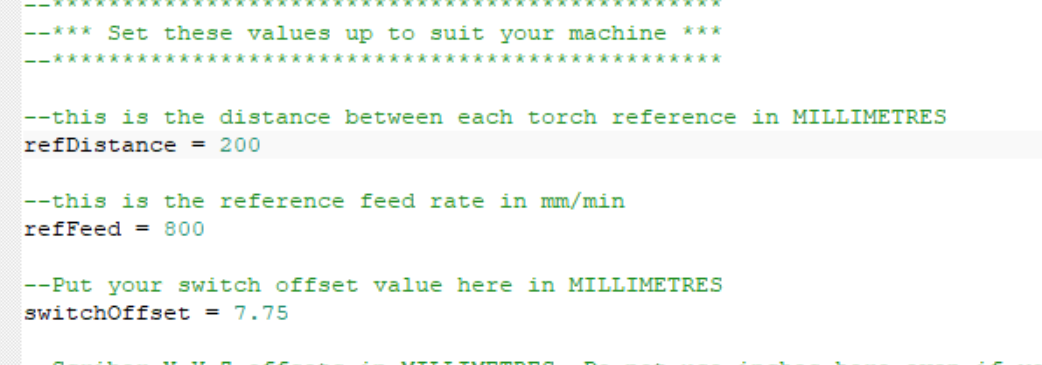

Programmation of Z probing is done by the post processor ( i use sheetcam post processor ) .

My head goes done ( Z axis move ) , when torch is on the metal sheet the second carriage goes up until it hit the z probing limit switch . I know that the distance between the front of my torch and the limit switch is 7.75 mm , si now my z axis goes up 7.75mm and i have my Z zero.

I can also setup in my post processor to do a probing every time that my torch make a move longer than 20 cm ( example ) .

My post processor config :

Z FLoating head for Plasma cutting (OX CNC compatible)

Build in 'Plasma Cutter Builds' published by mytechno3d, Oct 9, 2018.

How to convert your OX CNC to a plasma cutter at low cost

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

3dkaj, RGUERI1, Fungki isnanto and 9 others like this. -

-

Build Author mytechno3d, Find all builds by mytechno3d

-

- Loading...

-

Build Details

- Build License:

-

- CERN (CERN-OHL1.2+) Open Hardware Licence

Reason for this Build

Transform my OX cnc to a plasma cutter -

Parts list

-

Attached Files:

-