This is a relatively small and compact Z Axis for the ACRO motion system. The primary reason for me wanting to add a Z axis was to change the z height of the laser to accommodate various material thicknesses, as well as changing the height for multiple cutting passes.

I wanted to try to stick to as close to the original plates and design aesthetics as stock ACRO system. Used all OpenBuilds parts, with the exception of the NEMA 17 pancake motor. The motor mount at the top is a 3D printed part. Each of the two sections of rails only need to be 150mm. So I purchased the smallest rail available, 500mm, and cut it down. The lead screw also only needs to be 150mm, so again, I purchased the smallest one OpenBuilds offers, 290mm, and cut it down. I could have sourced a 150mm lead screw, but there wasn't much difference in price just to get the longer one from OpenBuilds and know I was getting quality. This was designed around the Opt Lasers PLH3D-6W laser head. As such, the mounting holes on the Z plate were cut with that in mind. To use this with a different laser head, other holes may need to be cut.

As I currently have built, I can get 60mm of travel in the Z axis. It could be upped to 75-80mm by drilling a new mounting hole for the limit switch. (I'm currently using one of the pre-drilled holes on the OpenRail.

This new carriage only adds about 22mm of width over the stock carriage. (So you'll lose about 11mm of X travel in both directions.) And it adds about 11.5 mm of thickness to the front of the carriage. So you'll lose 11.5mm of Y travel.

If you have an enclosure, you may need a little more clearance above the carriage. 68mm of extra height to the carriage. (That's with the pancake motor.)

The larger plate replaces the stock front plate of the X carriage. (Rear plate where the X motor mounts remains the same.)

I've assembled the axis, and tested the motion, and all looks good.

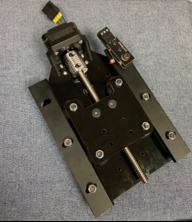

Render and images of assembly:

Assembly installed on the ACRO.

Also attached video of the assembly in motion.

Z Axis for ACRO

Build in 'Laser Cutter Builds' published by romamaker, Mar 23, 2020.

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

Kris Goorts, Glenn Weston, Tobias Fletcher and 4 others like this. -

-

Build Author romamaker, Find all builds by romamaker

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

To add a small Z axis to the ACRO motion system. Allowing for easier adjusting of a laser for either material thickness, or adjusting height during multiple cutting passes. -

Parts list