Hi All!

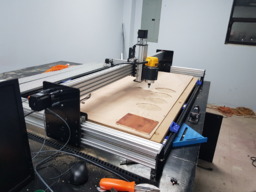

Originally started building this kit before OB was selling it, and was originally a 1510, then adjusted to make room to fit a 48" wide sheet so I can cut full sheets of material. Very much inspired by @Serge E. 's myOX, and @Antonio Pereira's plate mod. Total cutting area right now is just under 50"x30"

Side Note: Why is the Sphinx designation the opposite of the workbee? Got a little confused there, haha. IE Sphinx 1050 is 1000x500, but Workbee 1050 would be 500x1000...

Leadscrews on all 3 axis, and running a CNC Xpro controller. Still need to clean up wiring and put it in dragchains, and wire up limit/homing switches. Everything is controlled via raspberry pi and bCNC, so it's a nice setup to work with. The extra 2080 extrusion will go on to support the bed after I cut it down, and the leftover will go to a CBeam Machine or something. Thinking of laying out the bottom similar to the base of the sphinx maybe. Also plan to cut some extra plates to put on the inside to help support the x axis, as discussed in the main workbee thread.

5 start 1-2-10-ACME-DELRIN-NUT-BLOCK-RH-for-acme-threaded-rod-CNC-3d-printer

I came across these the other day, they are advertised as 1-7/16 inches tall, so they look like they might fit into the cbeam just perfectly. would be a good test for 5start 1/2 acme screws. I'm also contemplating moving to rack and pinion and large vbearings instead of the poly wheels, with a large x axis, they slip too much for me. v bearings may have a tighter lock, in addition to a rebuild of the plates

Workbee 1015 (50" wide by 30")

Build in 'Cartesian Style CNC' published by arcrunner, Jul 23, 2019.

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

-

-

-

- Build Progress:

-

- Build Complete!

frostsicher, Firemedic527, ynotjoe and 8 others like this. -

-

Build Author arcrunner, Find all builds by arcrunner

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA