The Laser Box

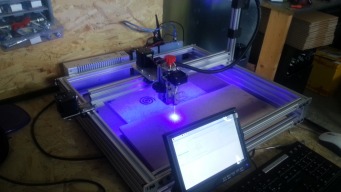

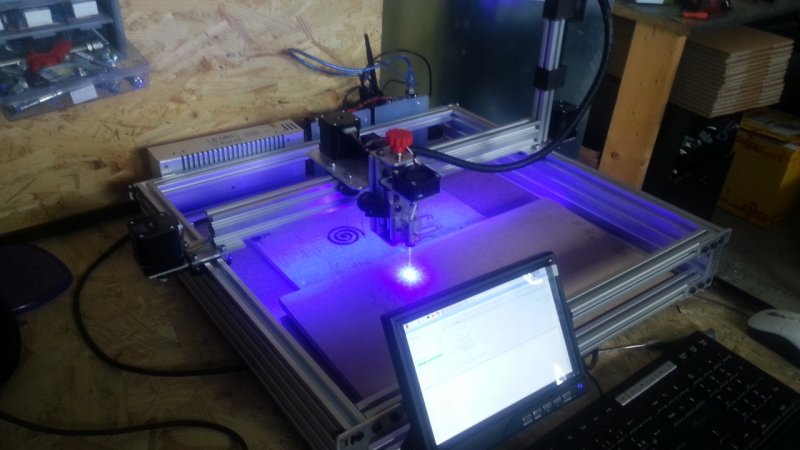

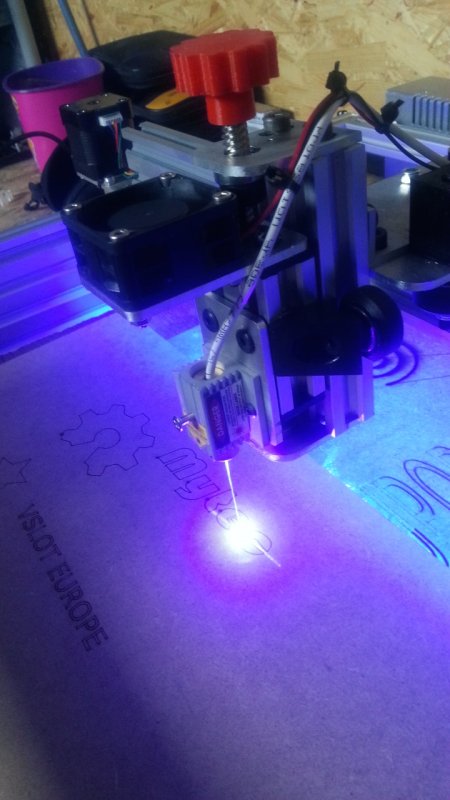

Goal : Creation of a cutting and engraving laser machine

First point : Excuse my very poor english , i hope you will understand my explanations...

For a long time I dreamed to play with a laser cutter.

I do not want to use CO2 Laser ( too hard to build and to setup).

So I choose a blue laser diode (445nm) for this job

***********************

***********************

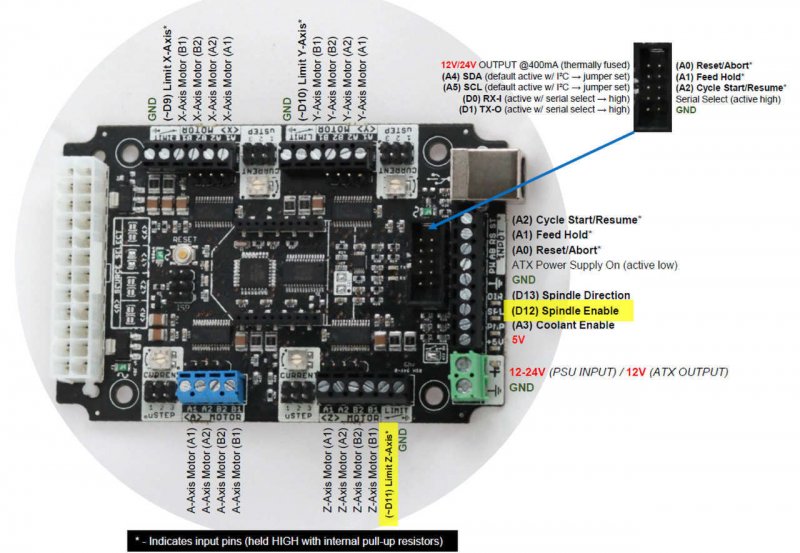

To control movements , switch ON and OFF and and adjust the laser power , i used a CNC X Pro controler board

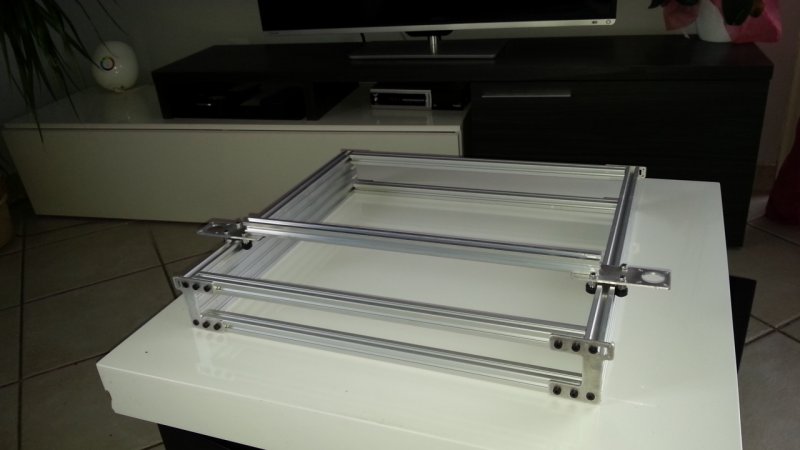

To make the frame i used some vslot profiles ( from vslot-europe.com)

I have cut specific parts using my CNC and make some other parts were made with my 3D printer.

The Laser Diode :

The laser Diode has a power of 2.8W ( diode + driver from chez JTech photonic)

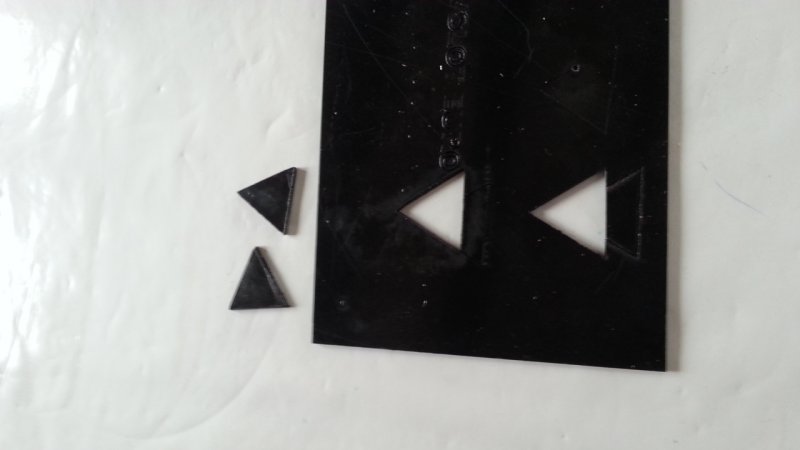

With this diode you can cut Foam , Balsa , acrylic ( it is a bit long ..)

You can also engrave.

How to switch ON anf OFF the laser and adjust his power :

The lighting of the laser is done using M03 instruction ( gcode ) and to switch OFF laser you must use instruction M05

Power adjustement is done using S0 instruction (normally used for the spindle speed variation)

The change can be carried out on 255 levels( de 0 à 254 )

Your GRBL file must be compiled before being downloaded to the controller card with a maximum spindle speed of 254 and minimum spindle speed 0

mods to do to the config.h file of GRBL :

*****************************

#defineSPINDLE_MAX_RPM254.0// Max spindle RPM. This value is equal to 100% duty cycle on the PWM.

#defineSPINDLE_MIN_RPM0.0 // Min spindle RPM. This value is equal to (1/256) duty cycle on the PWM.

***************************

Example : M03 S254 ( switch ON laser at full power )

M03 S127 (switch ON laser at 50% of power )

M05 ( switch OFF the laser )

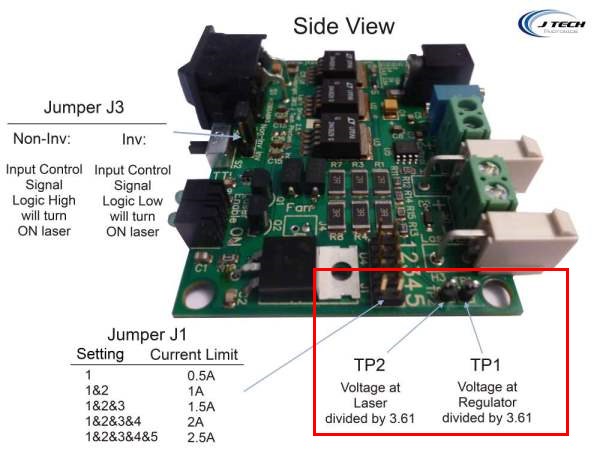

Laser Driver Current Monitoring Via MicroController

You can find more information for this application on the jtech photonics website

![[IMG]](proxy.php?image=http%3A%2F%2Fwww.openbuilds.com%2Ffile%3A%2F%2F%2FC%3A%2FUsers%2FMICHAE%7E1.IPA%2FAppData%2FLocal%2FTemp%2Fmsohtmlclip1%2F01%2Fclip_image016.jpg&hash=ab033429d51998cd305be08a7bcdee23)

Standalone machine

I add to this project a Raspberry Pi ( with raspbian ) and a 7’ LCD screen ,

so the machine is fully autonomous

I use grblcontroller to send the Gcode

improvement to come :

Add a stepper motor on the Z axis // Done , i will post some pictures soon

Enclose the machine to improve security

Make some ready to build kit and create a community aroud this project.

08/01/2015 : I try this build with 2 new electronic cards , 1 x Arduino Uno + gShield V5 and 1 x TinyG V8 , I think that the arduino + gshield V5 is the better choice because of the price and because we don't need all functionnality that come with the 2 other boards

After some months of inactivity on this build , i take the time to give you all files you need to build the laserbox frame ( dxf , solidworks , stl ...) .

I hope you will enjoy it .

If you have any questions please do not hesitate to contact me here or on the website www.vslot-europe.com

The Laserbox

Build in 'Laser Cutter Builds' published by mytechno3d, Jul 4, 2016.

A low cost and easy to build laser cutter based on 2.8w laser diode .

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Brian L Moore, Dragon31, barmaley and 13 others like this. -

-

Build Author mytechno3d, Find all builds by mytechno3d

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

Love the color of a blue laser diode ;-) -

Parts list

Qty Part Name Part Link Comments 1 Plates for laserbox http://www.vslot-europe.com/home/176-plates-for-laserbox-... Link -

Attached Files:

-