OVERVIEW

I designed this 3D printer mainly because my old printer, a MakerFarm i3v (a wonderful printer, really) could not reliably print ABS. This was largely due to the heated bed, and could have been fixed much easier than designing and building a whole new printer, but what would be the fun in that?

Creatively named Printer1, this build is meant to be a robust and reliable ABS machine. I originally designed the printer almost 100% using Autodesk Fusion 360, however, some of my files got corrupted so I switched exclusively to SolidWorks 2015. All the files can be found here: GitHub

I am also planning on creating everything in FreeCad, if that would be useful. Drawings of the parts I've made can be found in this build page, as well as STLs of the printed parts I made.

The final price in the BOM (uploaded in files) came out to just under 400 USD, but this is without a controller. I used a RAMPS 1.4 and Marlin firmware. I feel like you can build it for much cheaper depending on your sources.

BUILD PLATE

This printer uses a 5/16" MIC6 Aluminum plate as the build plate, with a 500W, 110V Keenovo silicon heater mat. The 8" x 8" build plate heats up to 120 C in about three minutes and stays there easily during the print. I've gone as high as 160 C and could likely go higher. Besides the thermal advantages of printing directly to an aluminum build plate, it also allows for easy implementation of auto bed leveling using an inductive sensor.

I used a mill to drill the three screw holes and then a flat end mill to create the "counterbore." After I leveled the bed when I installed it, I haven't touched it since; the auto bed leveling takes care of everything else!

X AXIS

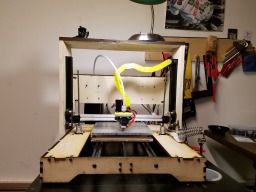

Besides the heated bed, the main component of this printer is the x-axis design. It uses a belt clamp idea which I designed based on Robert Hummel's Laser V build. Combined with a Bowden hot end/extruder, the x-carriage is very light and compact. The plate is CNC machined out of 4mm thick 6061 aluminum. I didn't feel like fixturing the plate down to anything so I just outlined with a ball end mill and then cut it out using a bandsaw, which resulted in not perfectly straight edges, but oh well. The holes are all that really matter.

FRAME

The frame was designed for laser cutting out of 1/4" and 1/2" birch plywood. I was able to purchase 12" x 24" sheets of wood from my local craft store and I ended up needing two of each thickness. I uploaded PDFs of the four full sheets needed to be laser cut. In addition, there are PDFs of all the individual frame components.

PICS & RENDERS

Here's some pictures of the mostly completed printer and some renders done in SolidWorks.

TO DO

Some things left to do include:

- Change to e3d Lite6 Bowden

- Design and make Bowden extruder

- Lengthening z rods and v-slot

- CNCing wheel plates

- Lengthening and re-drilling x axis v-slot

- Wire cleanup (maybe a separate control box)

Printer1

Build in 'Cartesian Style Bots' published by andrizzle, May 17, 2016.

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Robert E. Nee, Mark Carew and MaryD like this. -

-

Build Author andrizzle, Find all builds by andrizzle

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Reason for this Build

Wanted to be able to print ABS reliably and quickly. Also, had a good amount of free time to kill.Inspired by

Laser V by Robert Hummel, MakerFarm i3V, Lulzbot Mini, Ultimaker -

Attached Files:

-