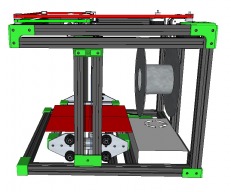

This is a remake of what was a box design (openbuilds.com/builds/corexy-enclosed.1362). After seeing David Bassetti's fresh air design at plus.google.com/DavidBassetti, posted to the OpenBuilds Google Plus, I started playing around with a more open design.

The design prints an 8x8x8 inch object and also encloses the PSU, Ramps controller, bowden driver and filament spool in a 17w x 16d x 15h area.

The design uses a CoreXY system running on idlers composed of F625zz flanged bearings. It also uses a bowden extruder design to take advantage of the speed capabilities inherent in a CoreXY system.

The Y axis uses belts instead of screws. The two belts run in between the two wheel guide uprights on each side. The two belts are run by pulleys attached to a drive shaft which is driven by one motor positioned below the build plate.

This looks like it will cost about $400 to build. I expect to start building on it in 2 weeks and will update either as the build progresses or upon completion.

PrintAir CoreXY

Build in '3D PRINTER BUILDS' published by Keith Davis, Oct 3, 2015.

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

-

-

-

- Build Progress:

-

- Build in Progress...

Sutrisno, imqqmi, konstantinpavlikhin and 6 others like this. -

-

Build Author Keith Davis, Find all builds by Keith Davis

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Reason for this Build

Attempt to match Ultimaker quality at half the price.Inspired by

![[IMG]](proxy.php?image=http%3A%2F%2F3dwrx.com%2Fopenbuilds%2FPrintAir%2F1.jpg&hash=38d1d908cb89416da990bae9e451b245)

![[IMG]](proxy.php?image=http%3A%2F%2F3dwrx.com%2Fopenbuilds%2FPrintAir%2F2.jpg&hash=803129362becf5008c78ef190f7da9f3)

![[IMG]](proxy.php?image=http%3A%2F%2F3dwrx.com%2Fopenbuilds%2FPrintAir%2F3.jpg&hash=860fc42834f6808ba036994f582751bb)

![[IMG]](proxy.php?image=http%3A%2F%2F3dwrx.com%2Fopenbuilds%2FPrintAir%2Fcorexy.jpg&hash=bac329130d2283ba9aa428ac232f2c27)

![[IMG]](proxy.php?image=http%3A%2F%2F3dwrx.com%2Fopenbuilds%2FPrintAir%2Fz-axis.jpg&hash=42f2f2c71450f519d8b82112c0ac9441)