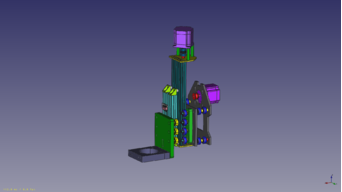

The idea is to make a Plasma CNC able to cut a full sheet of metal, investing as less money as practically possible. All the files are in the github, and we are currently housekeeping them to look nice.

The main features are:

It accept 4'4" x 8'8" sheet metal

NO NEED for crazy shielding /grounding! NO High Frequency Interference!! Plain electronics

It has THC.

V-Slot/ Belts

The gantry plates are modified. I actually cut them from plywood on my OX-like CNC router. Later I will use the plasma to cut steel ones.

Even though the table should be square and sound, any imperfections on the Z axis, will be absorbed from the THC. The plasma torch do not stress the railing system (no contact with the cutting material).

Table hardware:

Electronics:

- X railing is a 20x80 V-Slot 1500mm

- Each Y railing is made of [2] pieces of V-slot 20×80×1500mm next to each other. The minor gap does not affect the performance.They are bolted right on the side of the frame

- The slats (are not showing in the CAD for clarity reasons) are 2" wide flat bars that are inserted to cuts that are made to a 2.5" angle steel. They are resting on a 1" flar bar that is welded to the 2.5" angle.

- The table is made of 1"×3" rectangle tubing

Colossal Tech Cut-50F Plasma cutter----> NOT

For plasma I used the Harbor Freight Plasma as it is not HF start, and it does not need heavy shielding from interference. For THC I have the Proma SD right on the case of the Harbor Freight Plasma Cutter

24V supply

CNC shield v3.1 ./ Arduino UNO/ DRV8825 step drivers. I used a TB6660 for the Z, because it is easier to interconnect the THC

Nema 23 step motors for YYX, a nema 17 for Z

Proma THC SD for height control

Software:

Universal (Mach3 as a latest resort) g-code sender v2. the nighlty build.

For CAM I use Freecad/ Path workbench for now, but I will buy the SheetCam when I will have the money.

Pictures: Some pictures are in the folder "01 Design issues" on the github link above. A short video of my first cut is here

Soon with your help I will have a nice presentation of the build

Plasma CNC, 4'6" × 8'8" v0318

Build in 'Plasma Cutter Builds' published by polemidis, May 11, 2018.

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

-

-

-

- Build Progress:

-

- Build Complete!

-

Special Notes

Notify me if you want to help present this nice project to public. Its Open Source, my contribution back to the community. Its a proven concept, but I have so much time to create Parts lists, nice drawings etc. But The CAD file is great asset

MaryD and Mark Carew like this. -

-

Build Author polemidis, Find all builds by polemidis

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Reason for this Build

Because I need it to cut other equipment thatI am designing

(firewood processor, grapple, Compressed Earth Block, etc)

Open Source ToolsInspired by

OX CNC