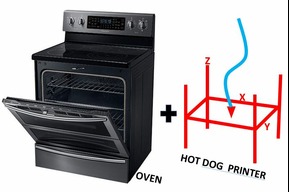

Purchased a used Samsung electric convection stove/oven from Craig's List to use for my build.

I think most any electric convection oven would do. I payed $30 for this one as the top cook surface was cracked.

I removed the bad top and back controls to prep for the printer.

Decided to deep clean while thinking of best way to implement design, may turn it sideways to have build volume Z axis in the taller direction.

Of the three heating elements, I will run a test for how hot the back fan/element alone does to heat the oven.

Can always add elements to the new oriented bottom.

Will need to remove the door springs with this new position to make it easier to open

May repurpose the control panel for the printer HMI to the right while filament loading to the left all to be mounted on a custom stand.

Oven Dog

Build in 'Other Style 3D Printers' published by Genetoys, Apr 6, 2021.

Building a printer that can fit inside and operate at ~200 C oven temperatures

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Jeffj, Mark Carew and Eclectic Hobbyist like this. -

-

Build Author Genetoys, Find all builds by Genetoys

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

1st printer- Ender 3 V2 (no enclosure) and saw issues with warped ABS parts,

2nd, printer- Matterhackers Pulse, purchased for my job with enclosure still had warp issues building larger parts.

I do not have the 7-10K to shell out for high temperature printer

This will be my 3rd printer/first build that will be capable of high temperature engineered plastics. for under 1-3KInspired by

I have not seen this done anywhere and draw inspiration from all the successful builders out there.