Looking for a set of lasercut parts to build one? Clockwerk Mech offering at $400 incl shipping in the US

Now that FreeBurn-1 is up and running (see http://openbuilds.com/builds/openbuilds-freeburn-1-v-slot-co2-laser-60-100w.1001/)

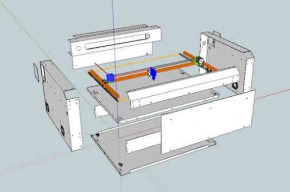

I think it's time to start working on my 4th iteration of a lasercutter design: FreeBurn-2-Mini

The Mini is a much smaller (900x650mm desktop footprint) machine that offers approximately 600x400mm work area, with a 40-50w tube (larger tubes need a longer body - so you would be better off building a FreeBurn-1 style machine if you want higher wattage)

Furthermore, the Mini will use a lot more lasercut/waterjetted metal sheeting (yes I hear you - but trust me every big town has a shop just hunt them down) with some strategic bends. Also, a BIG challenge is to make the whole design be bolt-together. If I could use spot welds my job would be a lot easier but then that would make reproducing the machine / packing as a kit / later disassembly impossible - and I'm not prepared to compromise those. No the FreeBurn-2 Mini will need nothing but a few bolts to assemble!

The sheetmetal frame will be easier to align than a FreeBurn-v1

So where do we kickoff this project?

1. 20 Jan 2015: Release the first render

2. 20-25 Jan 2015: Cleanup design - all those buttjoints have to change to planned bends with radii allowances and holes so all the panels can bolt together. I also need to draw the lid and z axis

3. Jan-Feb - finish drawings and ordered first prototype, plugin for sketchup to laser-gcode, etc - see the discussions tab for details

4. 19 Feb 2015: Alpha machine frame built! Released beta files for early adopters

5. 9 March 2015: Electronics prototype phase

6. On the hunt for a cheap US based supplier to lasercut and bend frames.

7. Saving up for the tube + PSU

UPDATE:

8. April 2014 - first movements

9. April 2014 - kickoff efforts to build a ChiliPeppr.com workspace to control the machine with

Donations received:

Alex Lee: USD $50 - Thanks Alex!

SevenBlue.com: USD $20 - Thanks Anthony Webb!

Dave M: USD$50 - Thanks Dave!

Donald D Parker: USD$10 - Thanks Donald!

Miquel Lluís Domingo Roca: USD$20 - Thanks Miquel!

Matthew Kusak: USD25 - Thanks Matthew!

Adam Glazer: USD$35 - Thanks Adam!

James K Rivera: USD$10 - Thanks James!

Larry M Mackey: USD$20 - Thanks www.LarrysAlaska.com!

Area 51 CNC Parts: USD$25 - Thanks http://area51cncparts.com!

Mark Carew: USD$180 Store Credit - Thanks http://openbuildspartstore.com!

Mario Rauseo: USD$50 - Thanks Mario!

Dave Hylands: USD$200 - Thanks Dave https://plus.google.com/ DaveHylands/posts

James Rivera: USD$55 - Thanks James!

www.smw3d.com - USD$75.56 worth of leadscrew parts + Shipping - Thanks Brandon!

<SUSPENDED THE OPTION OF DONATING VIA PAYPAL SINCE APPARENTLY IT GOES AGAINST THE LAWS IN MY COUNTRY - WILL TRY AND FIND ANOTHER WAY FOR YOU TO SUPPORT ME SOON>

If you could post a URL to your website/Google Plus or Facebook profile on the donation page it would make my shoutout to you much easier- or just Google Plus or comment in thread

Detailed Project Log and tonnes more pictures: Click the Discussion tab above

openBuilds FreeBURN-2-Mini V-slot CO2 Laser (40-50w)

Build in 'LASER - PLASMA BUILDS' published by openhardwarecoza, Oct 5, 2015.

A new mini version of the http://openbuilds.com/builds/openbuilds-freeburn-1-v-slot-co2-laser-60-100w.1001/ FreeBurn CO2 Lasercutter

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

-

Build Author openhardwarecoza, Find all builds by openhardwarecoza

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Reason for this Build

Lower cost, prettier looks for the office (aka less of a wife irritability factor) -

Attached Files:

-

-

Attached Files:

-