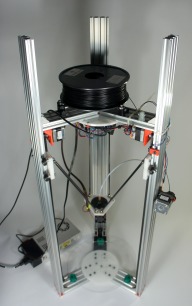

I've designed a 250mm size delta using primarily stock hardware and few 3d printed parts. While I got interested in 3d printing because of the reprap project, I think there can be simpler ways to build that a large selection of printed parts. This design uses mostly off the shelf hardware and laser cut parts. The current design still has a couple printed parts were it makes sense.

The connector plates, carriages and end effector plate are laser cut. For the first prototype, I used plywood, but expect to change to acrylic once the bugs are worked out.

Update:

I got great results with this build and have rebuilt with acrylic. The BOM is uploaded and I will have the laser cut parts available if you want to build your own.

MIY OLY Delta Printer

Build in 'Delta Bots' published by KBill, Sep 30, 2015.

Mag arm deltabot with laser cut carriages and connectors.

-

-

-

- Build Progress:

-

- Build Complete!

-

-

Build Author KBill, Find all builds by KBill

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Reason for this Build

This design was developed to minimize 3d printed parts and use as many stock components as possible. -

Attached Files:

-