MakerSL MSL-8 OB Vise

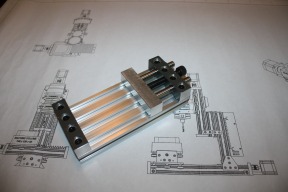

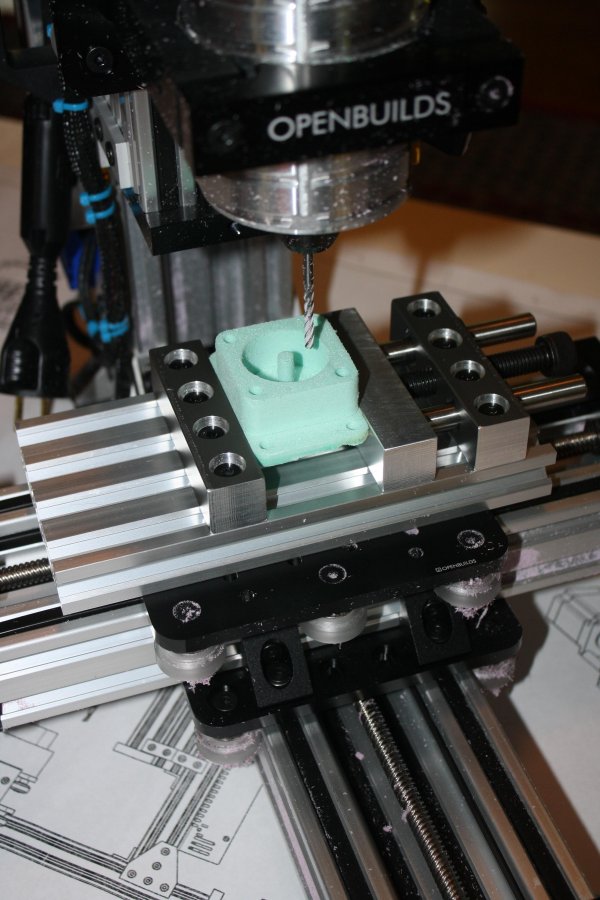

This Machining Vise was designed to be use with my CNC Micro Mill. It's adjustable and expandable. The rail is an Openbulds 20mmx80mmx175mm. The Stop Block and Drive Blocks are made from pre-Anodized 6061 Alm Bar Stock (.75" x .75"). The Slide block is raw 6061 Alm. It uses (2) .375" dowel pins and guide bushing as well as a M10 SHCS (all from McMaster-Carr). I used a M10 Helicoil in the Drive Block, but next time I might try a Keensert instead (if it fits). Total cost of the Vise is less than $50.00.

This would also make a great drill press vise and well as a bench top vise. Add a few V-Groves and you could hold PCBs, round stock, or whatever. You could also use Derlin or HDPE to make soft jaws (I have a set in the works). It might be possible to make from other widths of rail as well, I thinking 20x60 might work nicely!?!?

If you have any suggestions of comments head over to the "Discussion" section and let me know. If you find any errors in the drawing or CAD files please let me know that as well, and I will correct them as soon as possible.

Check out my ALBUM for additonal photos.

Check out the CAD Model HERE...you can view the assembly, and the parts, might be a nice tool in assisting with the assembly. If you sign up for OnShape you can copy and eidt the model at will. There is also a fully machined verison of this vise (in the same document), I modeled it first and then desided to use OB Rail instead.

Lastly, the length of the Vise (20x80 rail) can be increased or decreased to suit your needs without having to change any parts, the overall build or assembly of the vise...

Have fun,

Sonny

Update 11-3-2016

I adding some additional parts files as well as drawings...please see the "discussions" section for more details.

Also checkout GinoTheCop's C-BEAM-GTC for another use of the Vise...very cool rendering in the "discussions" section...nice work Gino!!!

Sonny

Update 11-4-2016

Expanding on Gino's Jaw Mod I have Modeled some examples of Soft Jaws that would bolt to the Aluminum Jaws and allow full customizing of the jaw sets. Check them out and let me know what you think in the "discussion" section.

Thanks for checking my designs,

Sonny

MakerSL MSL-8 OB Vise

Build in 'Everything Else' published by Sonny Lowe, Dec 11, 2017.

Small Machining Vise designed around 20x80 Openbuilds Rail System

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

-

Special Notes

Please keep in mind that all the blocks are Milled and will require some machining knowledge as well as a vertical milling machine (or similar). Hardware can be exchanged as you wish (pin sizes, bolt type, inserts, etc.)

-

-

Build Author Sonny Lowe, Find all builds by Sonny Lowe

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

I wanted a low profile, light weight vise for my Micro CNC Milling Machine. I wanted it simple and relatively easy to build. I also wanted to be able to adjust the location of the stock, cut small parts in the middle of the vise.Inspired by

Even though there may not be an exact build that inspired this, every build here makes us think outside of the box, and fills us with the desire to create and build... -

Parts list

Qty Part Name Part Link Comments 8 M5 x 15mm low profile screws http://openbuildspartstore.com/low-profile-screws-m5/ Link 8 T-nuts http://openbuildspartstore.com/tee-nuts-25-pack/ Link 1 20x80x175 V-Slot Rail http://openbuildspartstore.com/v-slot-linear-rail/ Link 1 M10x40mm SHCS (PN: 91290A220) https://www.mcmaster.com/mv1477933624/#catalog/91290A220 Link 2 .375" Dowel Pins (PN: 90145A634 https://www.mcmaster.com/mv1477933624/#catalog/90145A634 Link 2 .375" Flanged Bearing (PN: 6627K) (optional) https://www.mcmaster.com/mv1477933624/#catalog/6627K414 Link 1 M10 Helicoil (Optional) (91732A800) https://www.mcmaster.com Link Any type of insert can be used, nothing is required although durability could suffer without it. 1 .75"x.75"x 12.0" ALM Bar Stock (PN: 6023K49) https://www.mcmaster.com/mv1477933624/#catalog/6023K49 Link Makes all three, Stop, Slide and Drive Blocks. FYI: I would use raw stock next time around, the Anodizing on this stock was not very good. 0 Optional All Metric Hardware Listed Below Link 2 8mm Pins (91585A209) https://www.mcmaster.com/#standard-dowel-pins/=14vm59c Link You could also use 8mm linear rod as well (3D Printer Rod) 4 8mm Sleeve Bushings (5448T3) https://www.mcmaster.com/#5448t3/=14viv3d Link These are only 10mm long, so you could use four, inserting two from each side of the Drive Blaock 0 Link -

Attached Files:

-