This build has been made by students of Fontys Hogescholen Eindhoven department Engineering as part of a group project. We wanted to make a laser cutter with functionalities of expensive laser cutters on a low budget.

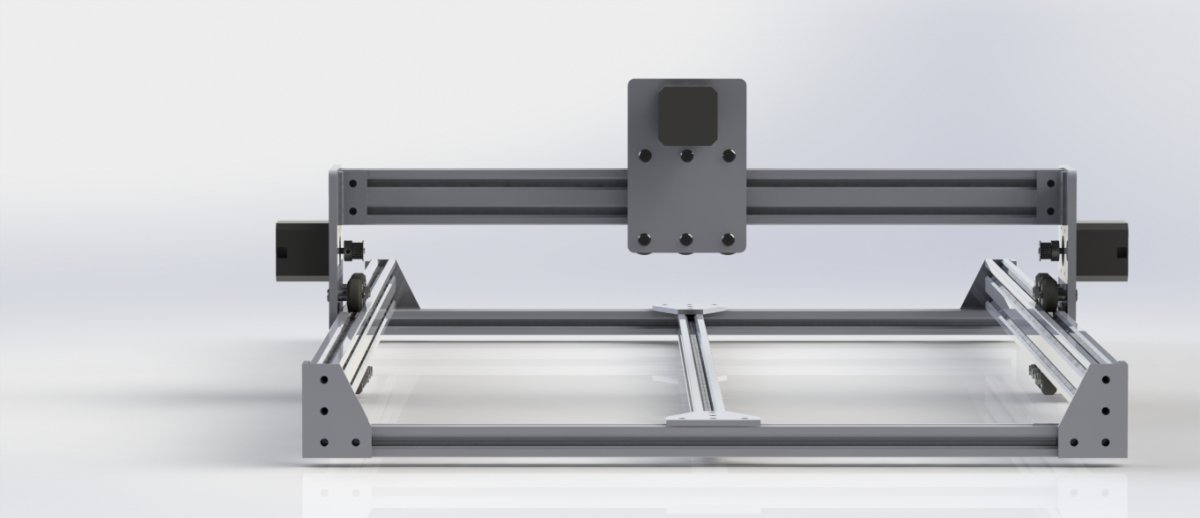

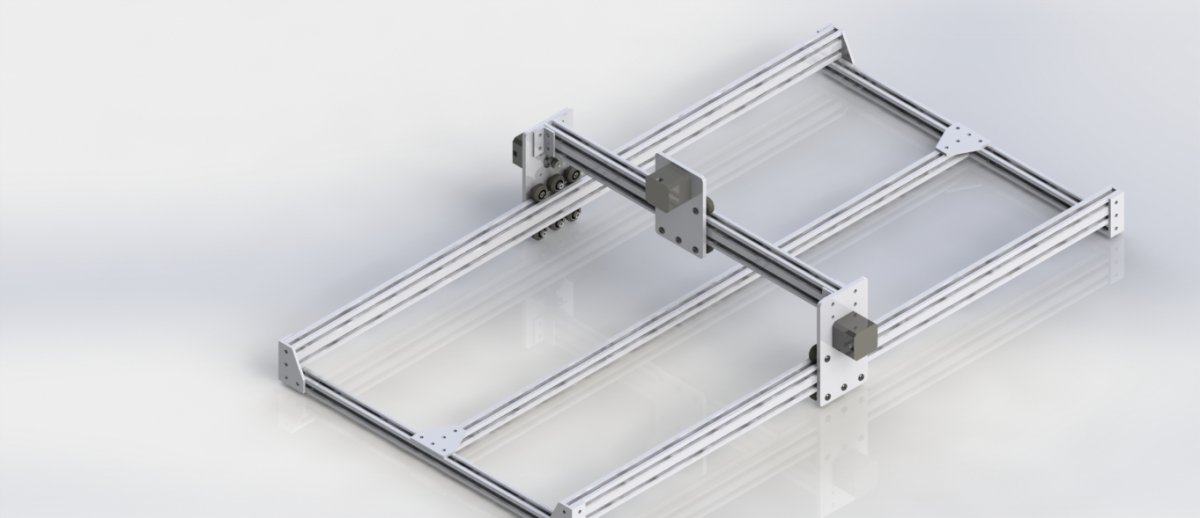

Step 1: The XY-table.

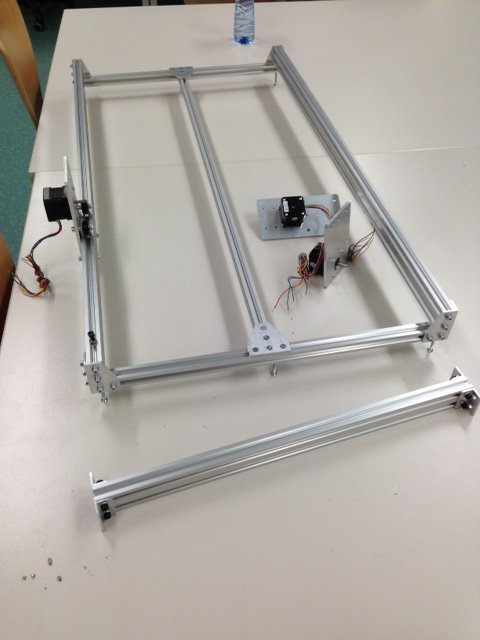

The team designed an XY-table as a basis for this project, keeping in mind that later on drivers, powersuppy, lasertube and mirrors, exhoust extraction and a protective casing have to be added. The design is made from Openbuilds parts, which we also used in our CAD model. It is based on many projects on this site featuring the OX configuration. The minimal workspace was requiered to be at least 300 by 600 mm, but we exeeded this by a lot.

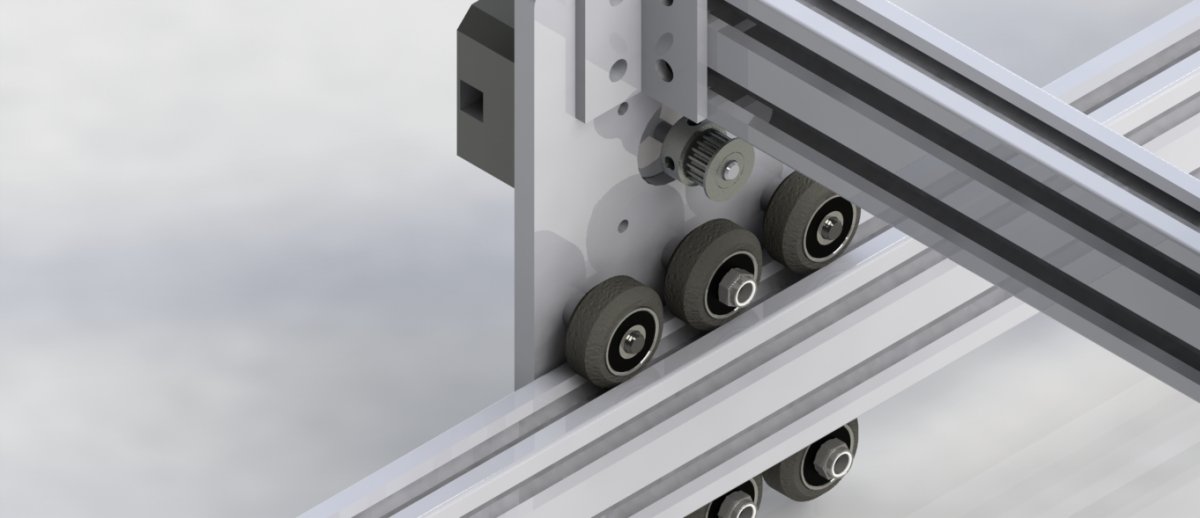

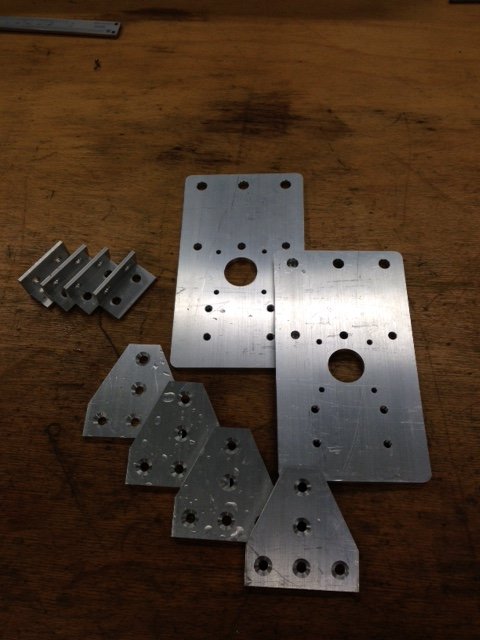

Steppermotors used are NEMA 17 with 0.9 degrees per step. We wanted to produce the mounting plates ourselves, becouse at our school we have access to a CNC mill and aluminium plate material was given to us for free by the workshop.

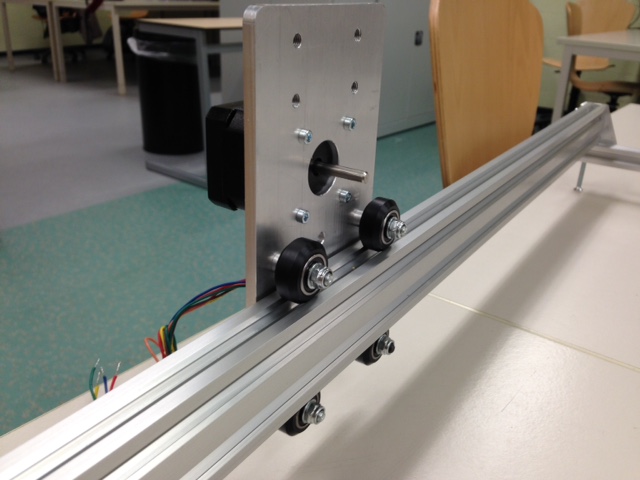

Unfortunately when we assembeled the frame, we encountered a problem. The wheels we ordered had a bigger diameter (which is good) than te wheels in our CAD drawing. That ment we had to make the plates again with slightly different dimensions. Final assembly of the frame could contiue and we were happy about the high stiffnes, low friction and low slack the assembly provided.

Fixation of the timing belts proved to be very difficult with the standard plates that slide in the V-slot. We will probably improve that later on. Also the corners of the axis that is mounted between the two plates are not very stiff and screwholes are positione too close to each other. Other than that we are happy with the result.

Laser cutter project by students

Build in 'Laser Cutter Builds' published by Sjors, Dec 3, 2015.

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

cüneyt savaş, Blueflame2007, Balu and 1 other person like this. -

-

Build Author Sjors, Find all builds by Sjors

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

This build was initiated by the need of our ObjeXlab for a laser cutter. The intention is that this will be made by students on a reletively low budget for their Expo project. Students can learn a lot from this project becouse it combines mechanical, electrical and software design, as well as implementing a laser. Also working in teams and learing the process of making design choises is an important aspect. Eventually this product will be used by our students and might even get certified to be offered as a kit for other schools or hobbyists.