I was asked by Beryl guitars some time ago if I would build them a CNC, having experience with my machine at home and being a sucker for a sad tale, I agreed.

This machine was going to be diffrent it was belt drive, completly new to me as my maching is screw driven, we spent the next month looking at machine kits and set ups, deciding the size was a start, with the possiblity of work from a local sign company we went for a 1500 x 1500mm machine,

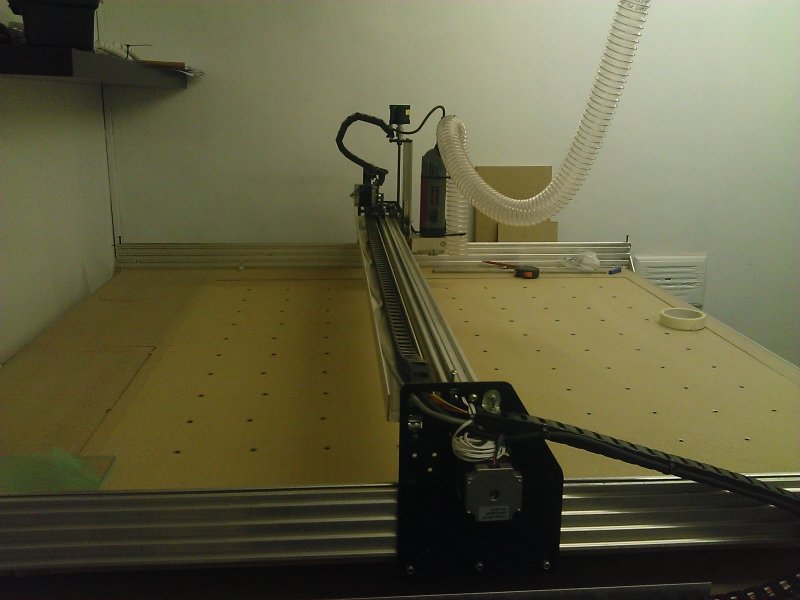

The machine was ordered and some time later a large box with other little boxes arrived, at this point we were still organizing the workshop and building benches and table for the CNC, table done we started the build and sorced a PC to control the whole thing

That was a month ago the machine is now built and runing, still a few jobs to do like fitting clips to the belts (we found the belt slipped) and build a shoe for the extraction, but we have cut stuff and I have ben quite supprised with the running of the machine, We might upgrade to heaver belts at some stage, have to see.

The machine is to be used to create custom Guitar bodies, necks and anything else it can do, plus the sign work so it will be kept busy

Loads of problems belt slip and flexing machine olny cuts very slow and shallow!!!

Update to our Machine:

After way to long to sort out our problems we are finally left with a machine that is capable of producing Guitars!

We had taken a good hard look at our machine and decided that in its present state, as supplied it was not up to much, so major re-think was needed,

We started with cutting the machine down in size, we reduced the old X axis (now the Y axis) to 1000mm therefore reducing flex,

The old GT2 belts were out the window, and GT3 3mm belts and pulleys in their place

I found the frame screws supplied in the kit were sub standard so purchased a load of better screws.

I have fitted idlers to the X axis to increase lap angle.

I am in the throws are producing 20mm higher corner plates to give us a better Z clearance, might make these in Aluminium or Tufnol.

The results of our labour has produced a machine that will not slip belts no matter how hard we push it! we had it running today on hardwood at speeds I did not think possible and it coped well

At last we can start production

Guitar shop CNC

Build in 'CNC ROUTER BUILDS' published by John foale, Jun 2, 2015.

Great bit of kit time will tell if it is up to the job

-

-

-

- Build Progress:

-

- Build Complete!

Smfuller, sigrx73, bernierunns and 2 others like this. -

-

Build Author John foale, Find all builds by John foale

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

Guitar productionInspired by

My own CNC and to have to build a diffrent machine