GrOX

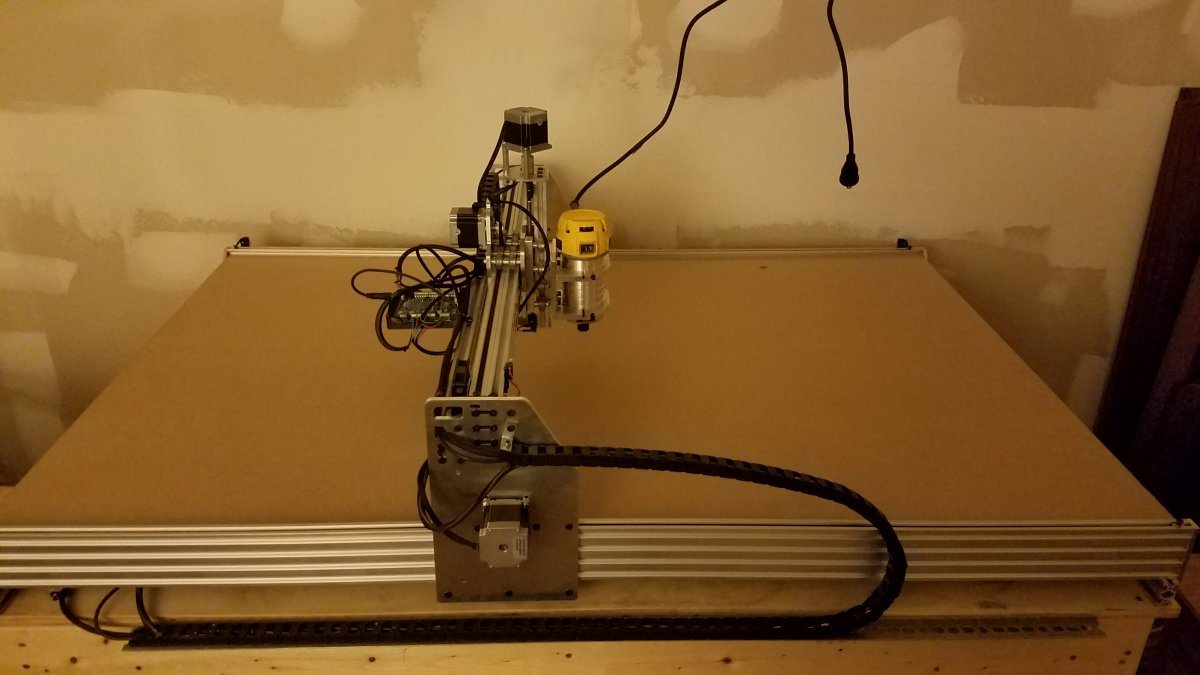

The initial configuration of this router is going to be pretty similar to a lot of other OX builds, but I have some modifications planned for later.

Basic Specs:

1000mm X 1500mm with about 5" of tool clearance.

TinyG controller

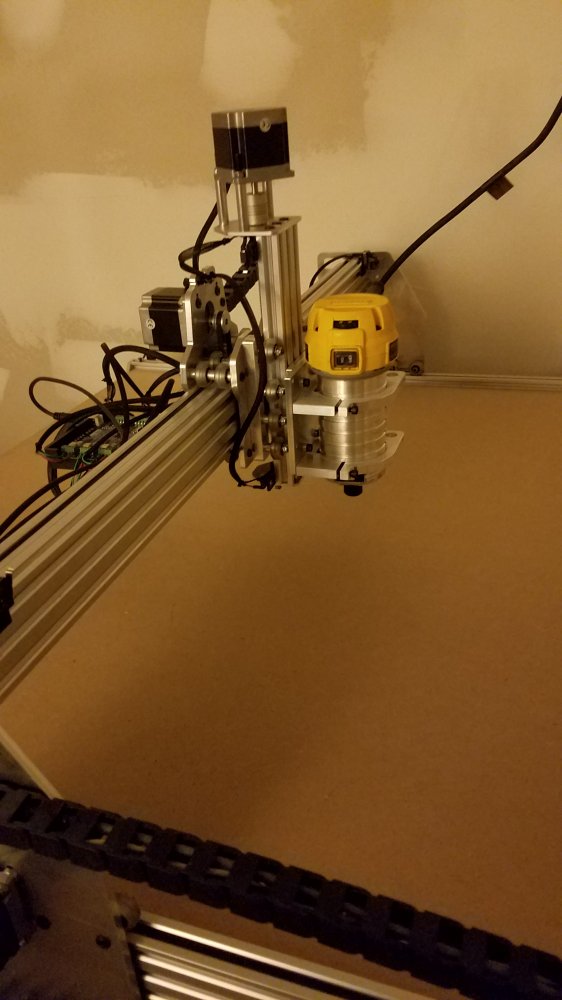

DWP-611 spindle

I uploaded a full parts list PDF

The first step was to inventory the 870 parts (not including tools)

Then I built a new workbench sized for the router. I still need to rip an edge on my table saw, but it was too late last night so I will do it this evening.

And I mocked up the X carriage, just to see how it would go together. Obviously I needed to disassemble it because I hadn't first done the Z spacers and wheels...

I have the front plate of the X carriage wheeled and tensioned

First Gantry plate

Second gantry plate started, but I shorted my list by 4 wheels because I added the extra wheels to the X gantry

9/3/2015

Got my second shipment from openbuilds today with the m5 X 20mm screws and 4 extreme wheels that didn't make it on my first list. Love the fast turnaround on orders... AND amazing customer service Openbuilds! While my first order had been short 1 t-nut and 1 grubscrew (setscrew) I was happy with how close the initial count was... But Openbuilds wasn't, And they sent me a replacement pack of t-nuts and several grub screws with my parts order.

That's the kind of customer service that I learned working for Das Maus and that I brought to my company... it's the kind that brings repeat customers and word of mouth referrals.

Thank you to OB!

I completed the bolt-together construction of GrOX today and I will start on the frame and Tapping tonight.

9/3/2015 pt. 2

Doh! First time tapping holes. Snapped the Tap off in the third hole on the Z rail. I must have tipped the drill or overtorqued the bit.

My bad.

Done for the night. Off to get a hand tap tomorrow and I ordered a replacement 2060250. Could have been worse.... like on one of the 20801500s.

9/4/2015

I picked up a replacement tap (manual type) this afternoon. Wasn't expecting to get anything done today, but ended up staying home instead, so I got some work done on GrOX.

I tapped my two 20601000 beams and bolted one side to the gantry plate. Manual tapping sucks, but it gets the job done. I need to 3d print some handles to cover the stupid metal rod on the tap.

I put on the X carriage (minus the Z rail, I had to order another, the broken tap is stuck inside... I can use the piece of extrusion for something else later...), remembered to insert the t-nuts, and bolted the other gantry plate on the other side...

then I went to attach the cast brackets, but I noticed that there were little nubs on the side meant to index into the v rails... but on a flat plate they got in the way. I clamped a file to a workbox on the bench and filed them off one side Wasn't expecting to have to do it, but aluminum files off easily:

Next I tapped the 20401000 extrusion... manual tapping is a pain in the wrist

I added t-nuts for the angle brackets, bolted the part on and added the angle brackets...

then I remembered that I forgot to put in the t-nuts for the TinyG controller box I am designing... so I took off the rail added the t-nuts and reinstalled it.

Here is a shot of the back of the gantry showing the 20401000 extrusion... when I was looking for pics of other builds, I couldn't find one of the rear of the gantry...

A couple things I noticed in the assembly, the two 2060's slightly bow away from each other in the middle... by less than .5mm, but it will add friction, and from top to bottom, there is a width difference of about 1/16th of an inch (English tape measure, sorry) the extrusions were cut just slightly off square on one side... I am going to take the side off and apply a little file action to manually square up the ends. small errors add up, so a little extra work now will make better routing laterIf I were a proper machinist, I would probably have checked the ends before I tapped and assembled the gantry.

9/5

The replacement 2060250 extrusion arrived from OpenBuilds... love their quick turn around. Busy family day, so other than updating my build journal and parts list, no work on the router today. Hopefully I will get some shop time tomorrow so I can file down the gantry rails.

I will upload the .stl files for the TinyG controller box and the tap handle cover when I get a chance to render them.

9/6

Snuck down to the workshop and assembled my z Axes

9/17/2015

My wife had surgery, so my build is on pause until the beginning of October...

I found that some of the cuts from openbuilds are just slightly out of square, so I got a truing disk for my table saw and some fine grit sanding disks.

the piece of 2060250 with the broken tap end in it has become part of the saw... fits my miter gauge perfectly and replaces the wood extension I had on it quite well.. now I'm going to probably order some more extrusions to make a box joint jig...

Side Note: I found a nice TinyG enclosure design on thingverse... it fits the current version perfectly

TinyG Enclosure for Shapeoko 2 by cmross92

11/25 Make that end of November...

Her surgery went well, but life interfered... then I got distracted by the problem and I went to the forum and asked for advice... got some good advice and proceeded to not need it because my assumptions were wrong.

because things weren't lining up correctly, I assumed that the cuts were slightly out of square... the crappy square I had wasn't accurate enough to tell me what was going on and like I said, life interfered... but after some good advice for truing the ends, I ordered some parts from Amazon to make a crosscut sled for my table saw... and took the gantry apart... then I used my nice extended corner angles to lash the whole mess together so I could get a good look at exactly what the issue was... and guess what... I was wrong.

One of the 20601000mm beams was 1mm longer than the other two extrusions.

well, I wasn't about to try to shave 1mm off of an extrusion with a table saw... I don't care how awesome the blade is... so I went back to my first method... sanding the end down... it took about 16 minutes... 15 minutes of which was setup and calibration of the miter gauge to the blade... then I carefully sanded off the offending millimeter.

then I unscrewed everything again and put it back together.... then I took one side back off and put the t-nuts in that I forgot for the angle brackets and the TinyG enclosure that I printed on my prusa i3. (I really dislike the i3. I think that when GrOX is done, I am going to order some more extrusions and build a delta from the parts.)

SO... in 2 months, I took my gantry apart 2 times and fixed a problem... plus I noticed that some of my screws are the wrong length, so I ordered some more... the thick corner pieces are really nice and sturdy, but 10mm screws don't quite engage enough and 15mm are too long... so I found some 12mm ones on ebay and they should be here in a couple days... for the purpose of ganging the extrusions together, I used the t-nuts backwards.

I may get to do a little more work tomorrow... but given that it's Thanksgiving, maybe not until next week... (this weekend I am escorting my lovely writer-wife to a literary convention (that just happens to be hosting some panels on Maker stuff that I might sneak off to see))

Happy Thanksgiving.

12/8

Ok.... so I suck at blogging... I've had broken bits of time between one thing and the next to get work done on GrOX... Short update, Mechanical assembly is pretty much done. I had to disassemble the gantry and 2080 rails again because I forgot to put the tnuts on for the belts and end-stops... of course I am not sure that I located my z end stops correctly yet... I will have to function test all of it before I am positive that I like where they are... (the Y axis stops are on the front edge rail so I can adjust them more easily... the X stops are on top of the gantry atm, and the Z stops are on the back of the z rail, set to bump the wheel spacer block)

Things that I have noticed...

1) Using Chris's nice beefy corner brackets means you have to either source m5x12 screws, or use washers on m5x15s... not a big deal, but openbuilds doesn't sell m5x12s and I was unable to find matching screws... so I have button heads on those... the use of a double stack of shims looked worse.

2) I'm not really confident of the resilience of the end stop switches from the openbuilds store... they probably work great for smaller CNCs and 3d printers... but they seem a bit small for my machine... I will give them a try though. I'm just used to seeing beefier end stops I guess... though my printer has switches like this.

Things I have (re)Learned.

1). Measure and recheck and re-measure.... I cut an extrusion short because I misread my tape measure... it's just slightly short, and it will work, but I wish I had cut it right... I am going to replace it anyway because I decided that I wanted a bigger support extrusion... and it's more than long enough for the Kossel I am going to build next.

2). If you don't really pay attention to other people's build videos, you will end up re-doing work. I didn't put my steppers on before I mounted the gantry, so I had to take off the gantry... I didn't put enough t-nuts places, so I had to add t-nuts... etc. A bit more planning would save wrist work, but I am having fun.

I may get to do some wiring tonight... woohoo.

2/22/16

wow... life sneaks up on you.

lots of updates to write and photos to upload.

the short of it, Wiring Done, Motors working correctly. Just need to engage the belts and fill in the configuration file...

what is holding me back? I need to borrow a friend with a pickup to get some MDF from the hardware store... my trunk isn't quite large enough for the piece I need... and I sold my truck when my son was born. (only one row of seats, so no possibility of child seat)... I need a new (used) truck. Or to borrow one... second more likely, but my two friends with pickups have had busy winters, plus we had some nice bad weather.

I will try to get some more detailed updates uploaded tomorrow with pics.

4/22/16

I have to fill back in, but here is where I stand as of today:

GrOX is pretty much ready to rock except for configuring the TinyG and adding T-Track to the main surface. I added 2 layers of 1/2" MDF for a build surface but I am going to route in 3 T rails for clamps just outside the build area... and the scraps of the boards are going to be custom clampsjust need to order the extrusions.

Eventually, I will probably make a top out of 1-1/4" MDF covered in HPL and routed for the T rails and an inset that I can switch out... for custom MDF inserts (either drilled for vacuum clamping or screwdowns or whatever...

I have a cover and 60mm fan for the TinyG but I left it off for now because I need to do the trim-pots for the steppers.

While I have been busy with my other projects (my 3 year old son, home repairs, some conventions I work on, and remodeling my Prusa i3 into a Kossel) I figured out how to build a custom dust collector into my CNC table. I think that I can route part of the suction off for clamping too. I also have been talking with a co-conspirator about rigging a 60w CO2 laser on this bad boy as well... I can mount the tube under the table and pipe the laser through the scrap board with a piece of pipe that I can close off, and mount a mirror to the carriage side and the tool head, but I have to figure out if the machine will traverse fast enough to make it work. I will share plans for the dust collector after I finish getting GrOX running, since I'd like to cut the parts on the machine

(some Kossel parts using extruded aluminum corners from Folger Tech 700mm x 300mm)

-- The machine is finished. Woohoo! links to videos and new pics soon.

added to the files list:

added dxf of the end profiles of vslot rails.... for us old-timers who use AutoCAD

added 3d blocks zip for vslot profiles (acad 2004)

Working on a Q&D set of 3d models of the gantry plates for mockup, not manufacturing. I am really happy with the plates Chris Laidlaw made for me and will send people his way if ever asked.

GrOX (OX based router)

Build in 'Cartesian Style CNC' published by Jasen Stengel, Jul 3, 2016.

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

-

-

-

- Build Progress:

-

- Build Complete!

Mark Roberts, silopolis, Mark Carew and 2 others like this. -

-

Build Author Jasen Stengel, Find all builds by Jasen Stengel

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

experimentation and hobby