First things first. English is my first defensive language. So please forgive the my poor, poor spelling and grammar.

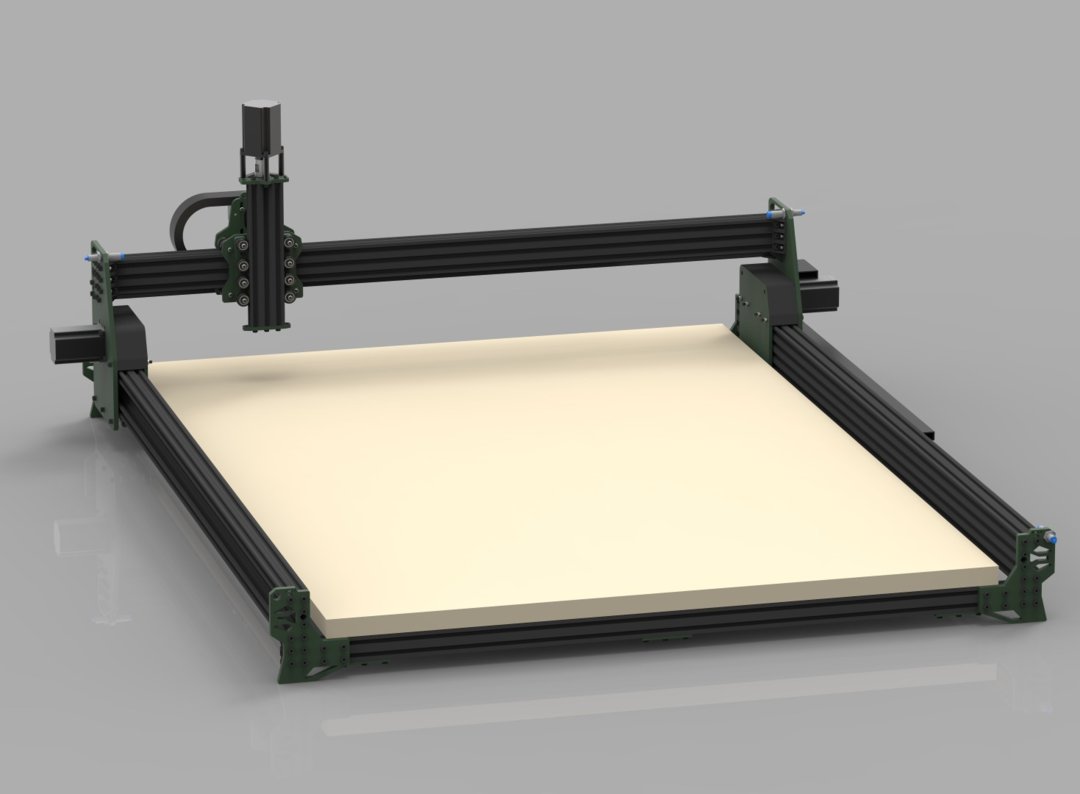

So about 2 years ago I was asked to build a CNC router for my work so that we can machine our own casting patterns. Naturally at some point I of researching CNC routers I ended up on the OpenBuilds website. The OpenBuilds style machine was a bit light for our needs, but the concept got stuck in my head. When I decided I want a CNC router for my self I designed it in the OpenBuild style.

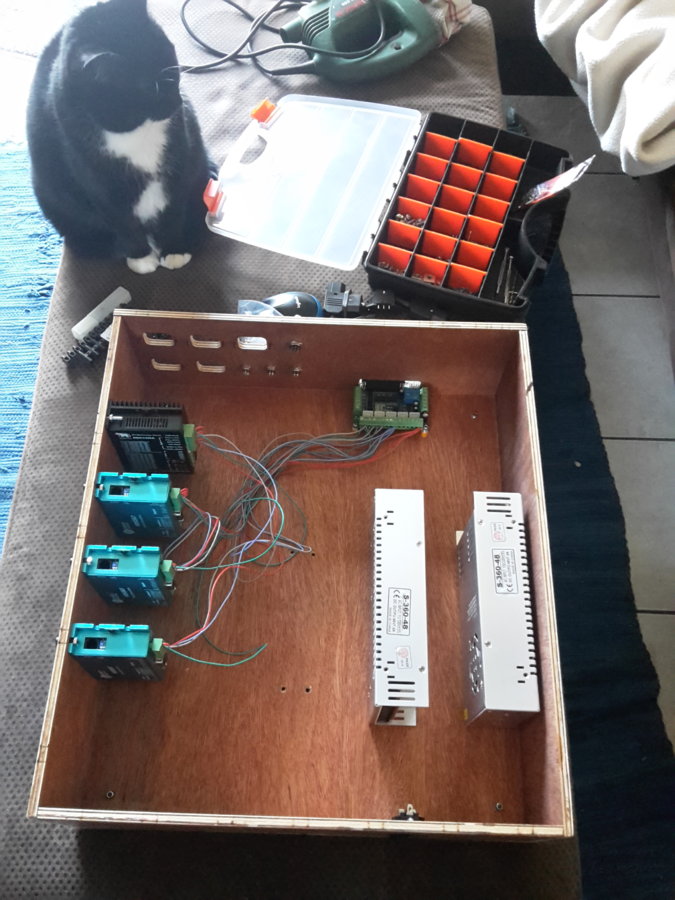

My big goal with my router was reliability at a affordable price. I would have love to be able to use some proper servo drives on my machine but there cost was just too high. Then I saw Martin Barfoed talk about these Leadshine close loop steppers on one of his YouTube videos and I fell in love with them. So I got to aliexpress and order me some. Well to say I'm impressed by these motors would be a grave understatement. They preformed brilliantly! Setting up the drives was a bit intersting, the configuration program is in Chinese, but when you get them to go, they go like stepper motor twice their size.

My breakout board did not come with a parallel cable and finding one in this day and age turned out to be quite a challenge. But after many phone calls and a lot of "you are looking for what?" awnsers, I finally found a place that still sells them. I love that it came in that off white color that all pc use to be.

Finally having a parallel cable I could test all my motor.

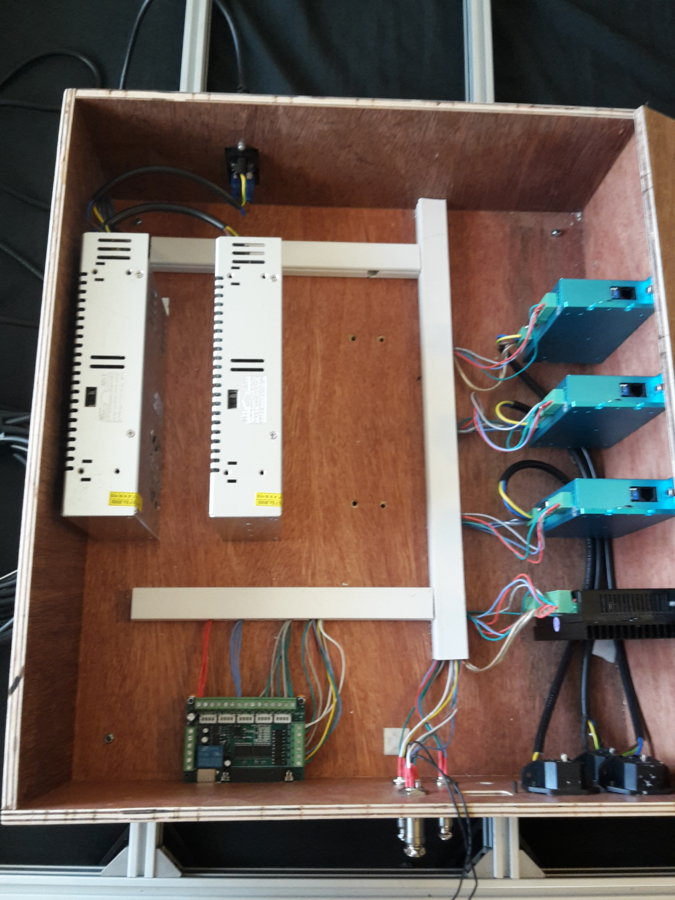

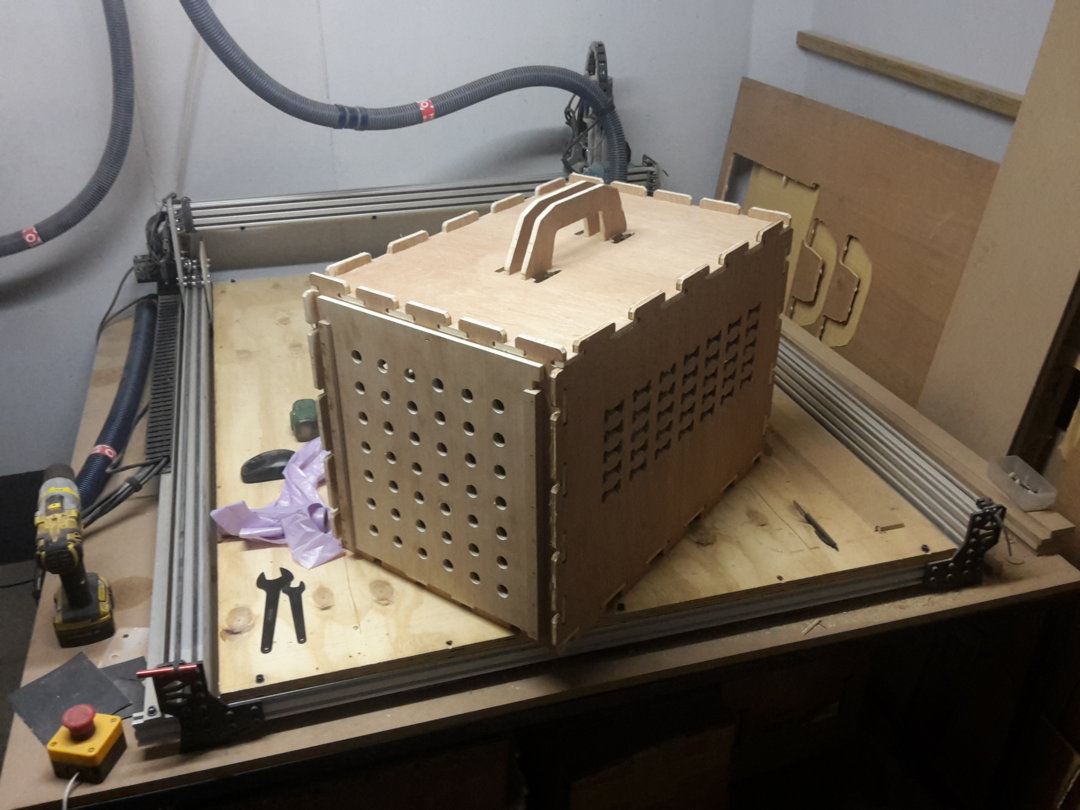

I made myself a control box with the work's CNC. Works well enough.

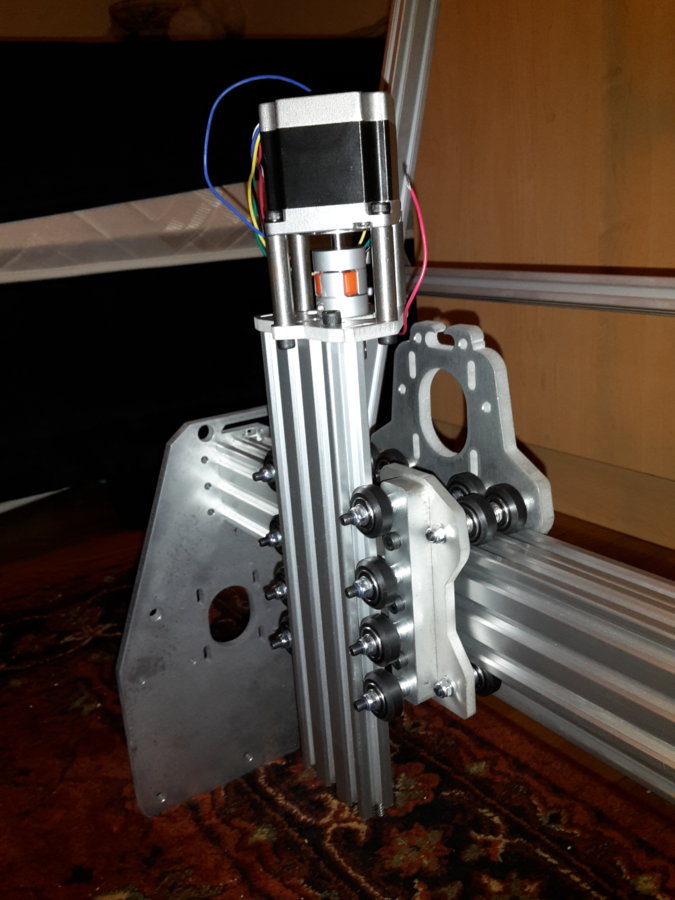

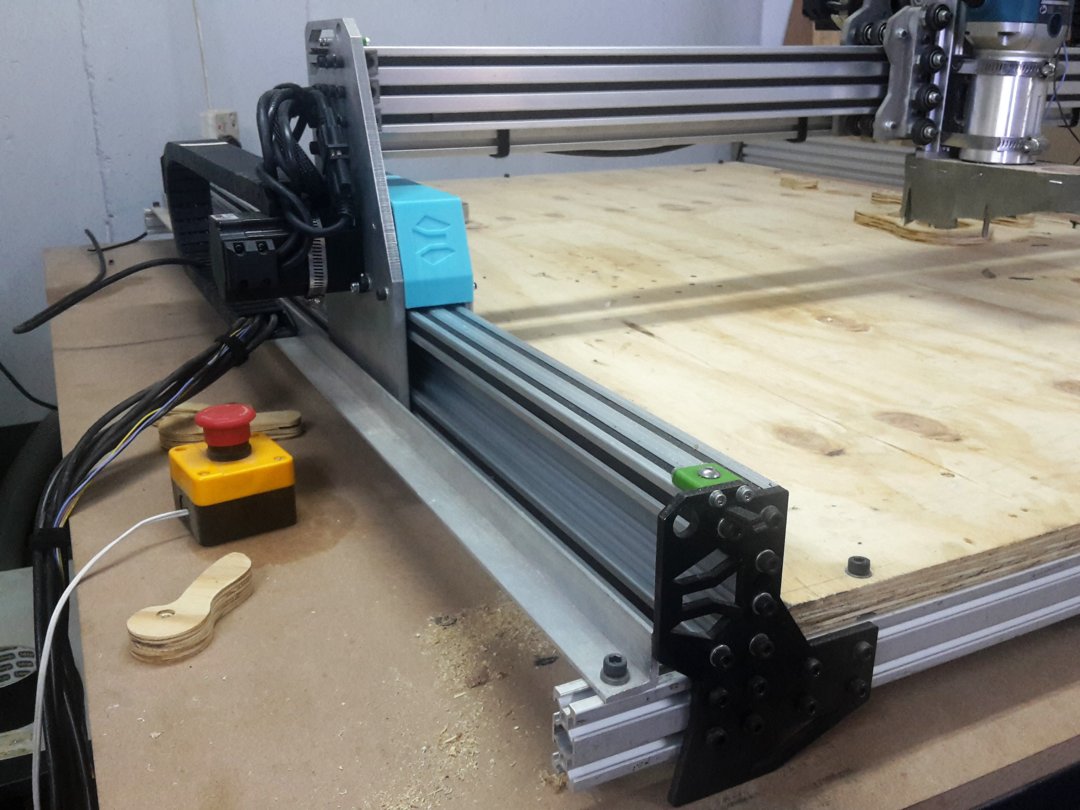

Got my aluminum extrusions. I had to mill them square because the supplier did not understand what square mend. I lost about 5mm on my X and Y axis because of it. My plate I mostly got water jetted. I was living in a small dupex, so I did not have a lot of space to build it. As you wil see later I ended up doing most of the build on my bed and had to sleep on the coach for like 3 mounths untill I found a bigger place.

The X runner test fitted.

All the wheels fitted.

I did not have spaces, so l used M5x1 washers to space my wheels.

I did some cable management in the control box.

Frame assembled. Wired and drag chains installed. On my bed...

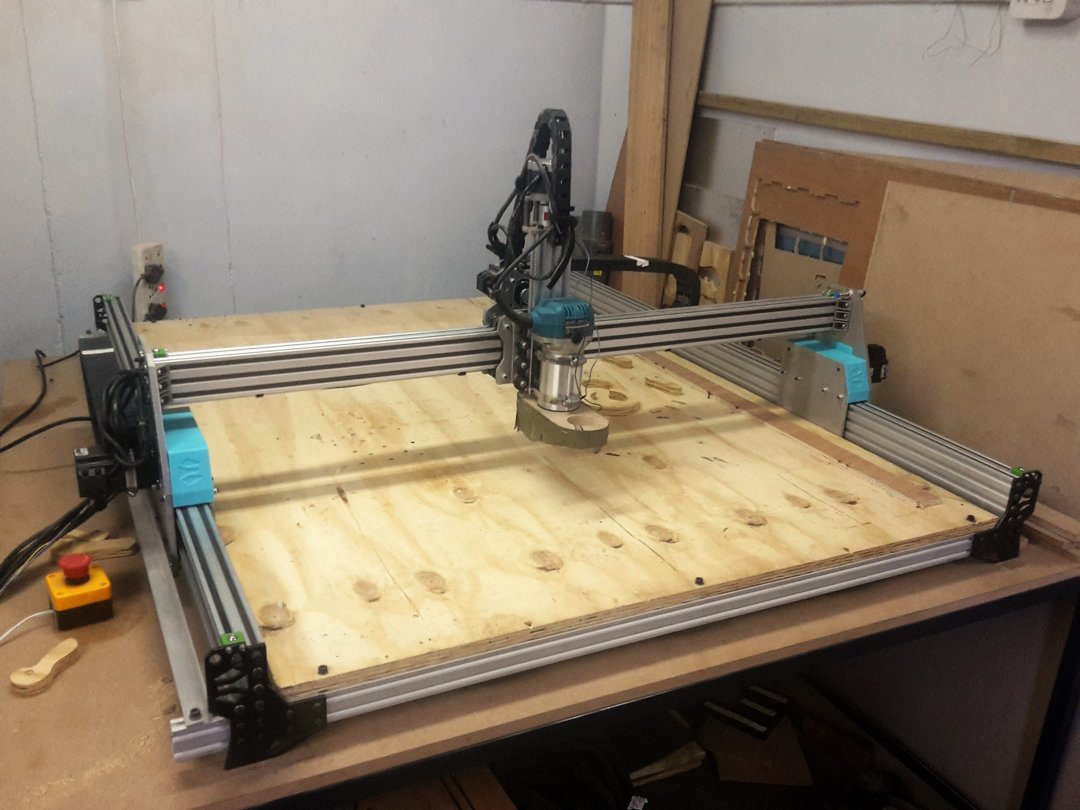

First time running and cutting!And yes i did run and cut jobs on my bed in my tiny apartment. Loud noises, dust everywhere and me carrying sheets of plywood in and out of my flat. ya..The neighbors tough I was crazy.

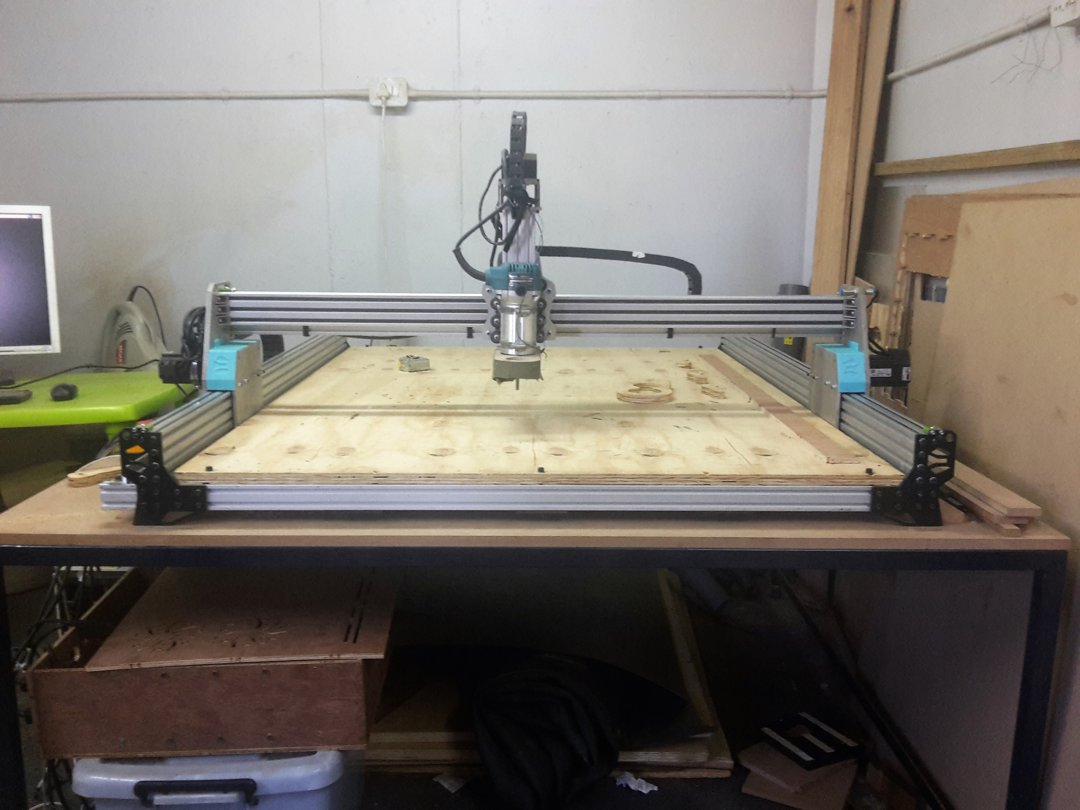

I found a new place to stay witch had a "garage" I could use as a work shop.

Build my cat a carry box.

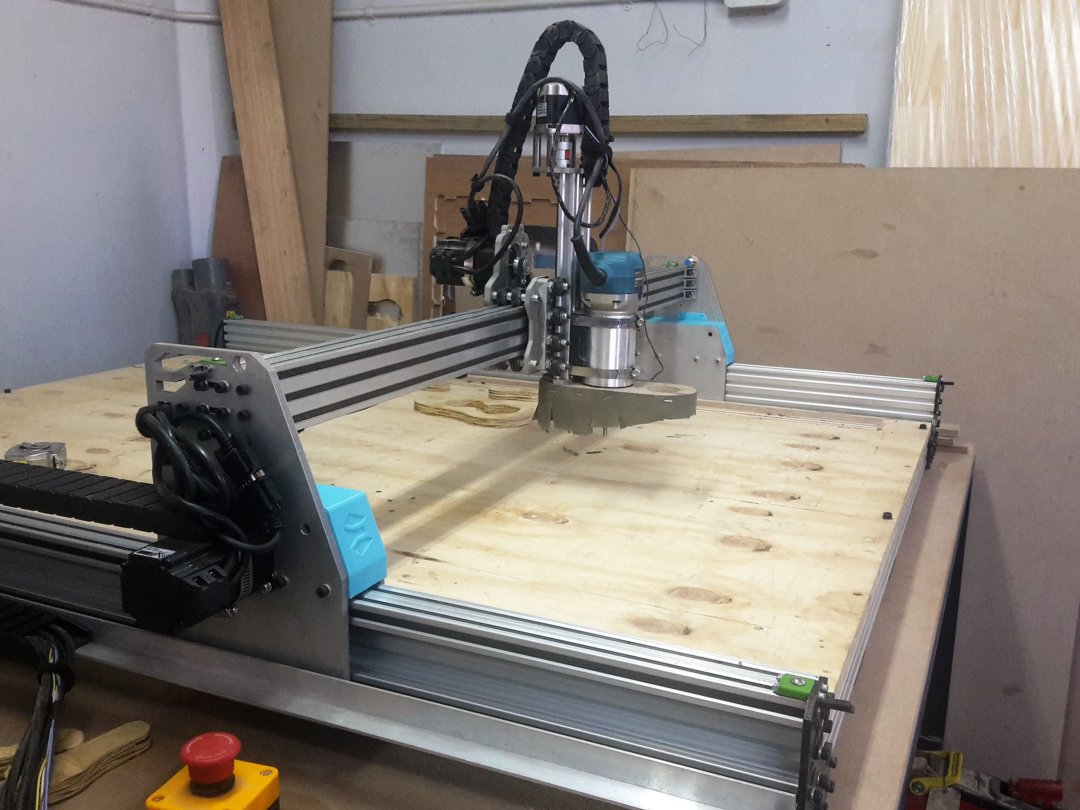

So this is where I'm at at the moment. I printed some covers and belt clamps. The router runs great.

EOX

Build in 'Cartesian Style CNC' published by Kazeki, Mar 12, 2018.

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

-

-

-

- Build Progress:

-

- Build in Progress...

Kukuruza, rick john, Anthony Bolgar and 6 others like this. -

-

Build Author Kazeki, Find all builds by Kazeki

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

World is coming to a end soon. Probably a good idea to have a CNC.Inspired by

Definitely Martin Barfoed with his Stainless OX build , Brian Oltrogge on YouTube (I'm inspired by everything he does) and RoverCNC ox.