This is an evolved version of Dash-X, previously submitted. Included here are an STP file of the main assembly, plus a zip file (Pack and Go) of the Solidworks 2022 source models. For those interested, Dussault (Solidworks) now offers a very low-cost way of getting Solidworks for hobby/maker purposes (non-commercial). Costs $100 a year, a very good deal indeed.

I will be updating the parts list etc. over time, so check back in if you need anything. Also please message me with questions, comments etc.

What's new here is the use of the e3d Hemera Direct (V6) kit, a major improvement over the prior Bowden extruder system. I have uploaded a couple of videos that depict the machine in action:

Also please note that I have included, for the first time, one of the Corner Stiffeners. I use a lot more than one, you may print as many as you like and sprinkle them around the machine.

Enjoy!

12/2022 update: I have added a pair of GH Enterprise GH Smart Shapers, which has essentially eliminated all ringing while still running at full speed (even faster!). This is the "icing on the cake" for Dash, I'm finally producing really great quality parts. Check it out: 3D Printer Controller - GH Enterprise

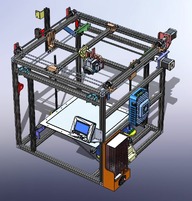

Dash X Direct, Cross-Beam 3d Printer

Build in 'Cartesian Style Bots' published by Neil Rosenberg, Dec 18, 2022.

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr

-

-

-

- Build Progress:

-

- Build Complete!

-

Special Notes

See the first version of "Dash-X" for a list of parts for most of this printer (Dash-X 3D Printer: Innovative design).

What's changed here is the filament delivery system, so instead of the BMG extruder and Creality hot end, this printer uses the e3d Hemera Direct Drive Kit. Also, you don't need the Capricorn tubing, any conventional teflon tubing will do.

Here are a couple of very useful Thingiverse parts that are included in this build:

Filament spool holder (use the Creality Nut and Bolt):Filler - The Customizable Filament Holder that fills your printer! by HugoHuge

Hemera Fan Shroud, I modified it in the Solidworks models for the specific screws I had. I even had to find a special low-profile screw to allow the fan to fit: Hemera 5015 Fan Shroud - Simple by permanoob

Chaingun427, Hans Petter, Ariel Yahni and 3 others like this. -

-

Build Author Neil Rosenberg, Find all builds by Neil Rosenberg

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - CC BY NC

Reason for this Build

Increased performance, better part quality, ability to use flexible filaments. -

Attached Files:

-