I recently finished my CoreXY based CNC Laser machine and I would like to share the build log with you guys here. So here's the build log:

The Plan

So whole project starts with a simple requirement and as said by a good man "Necessity is the mother of invention".

I started the project with search of fast drive systems with low torque requirement, initially I landed on H-Bot design but by further research I got to know that it require unwanted torque. To resolve H-Bot design issue there is a system called CoreXY. I found this design is followed by many 3D Printers and Laser engraves so I decided to build system based on this design.

The Electronics

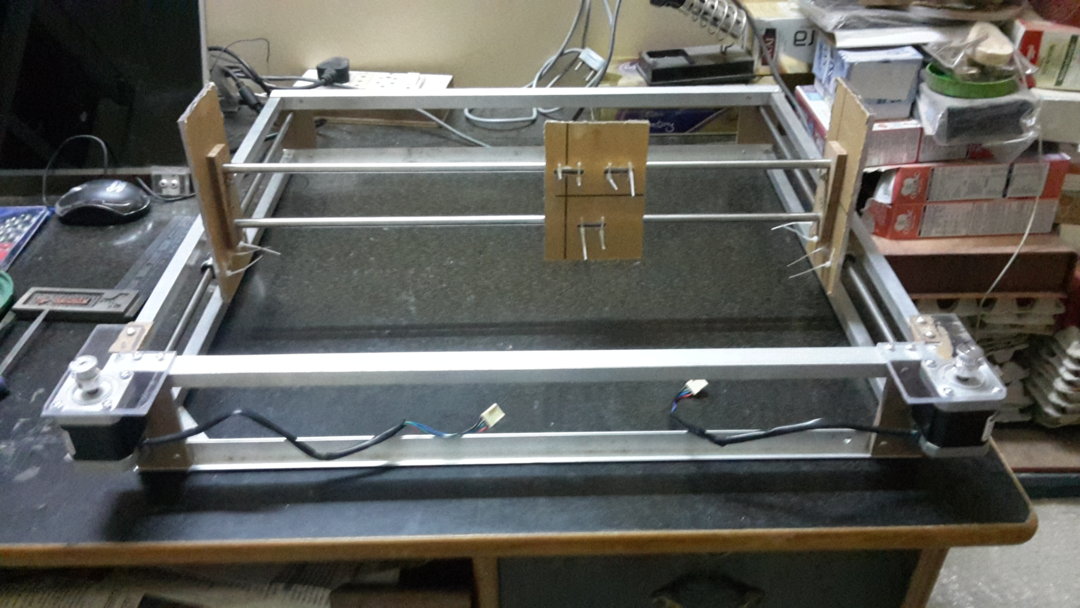

From my past experience with GRBL I selected the electronics based on Arduino. I wanted the circuit compact as conventional Arduino Uno is very big in size, so I took Arduino Pro Mini due to small in size and same microcontroller used on it. Next thing was stepper driver as I planed to use Nema 17 (4.4Kgcm) Stepper Motors, I selected the conventional A4988 Stepper Driver.

I fabricated the PCB at home to connect all the components together. First I tested the circuit on bread board.

After successful testing I created the PCB at home using toner transfer method. The result was pretty satisfying.

Finally I mounted all the components on the PCB followed by drilling process. I powered up whole setup with and PC Power supply.

The Body

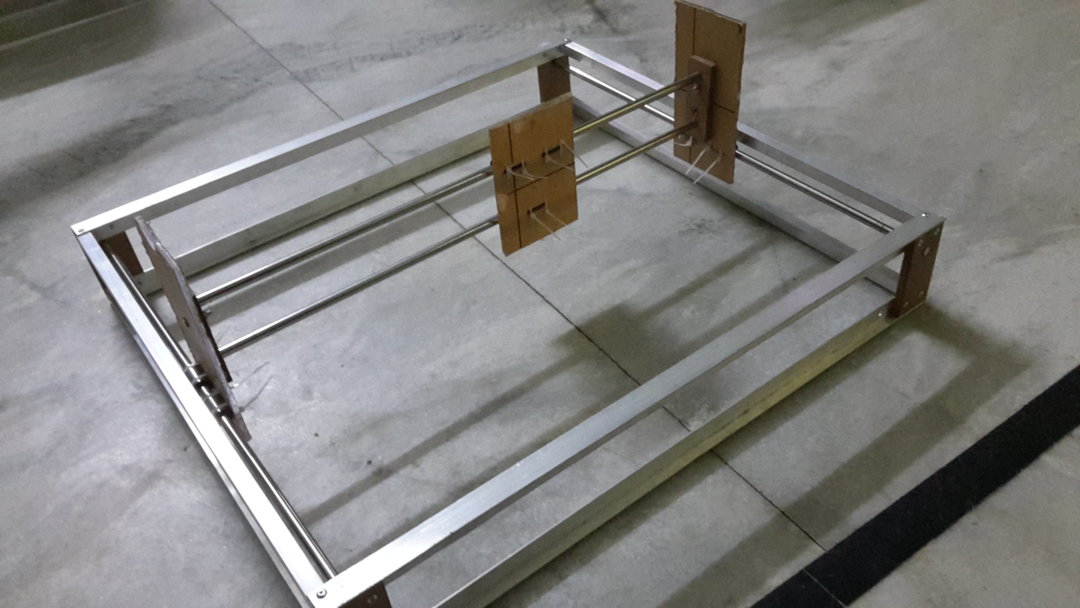

I wanted the body to be very light in weight and rigid enough. I planned a bed less body as I wanted it to be placed on any surface that is bigger then the working area (and it also decreases the overall weight).

I selected 3 materials 5mm Acrylic, 8mm MDF, and aluminium lengths of three different profiles (Due to lack of availability in local market).

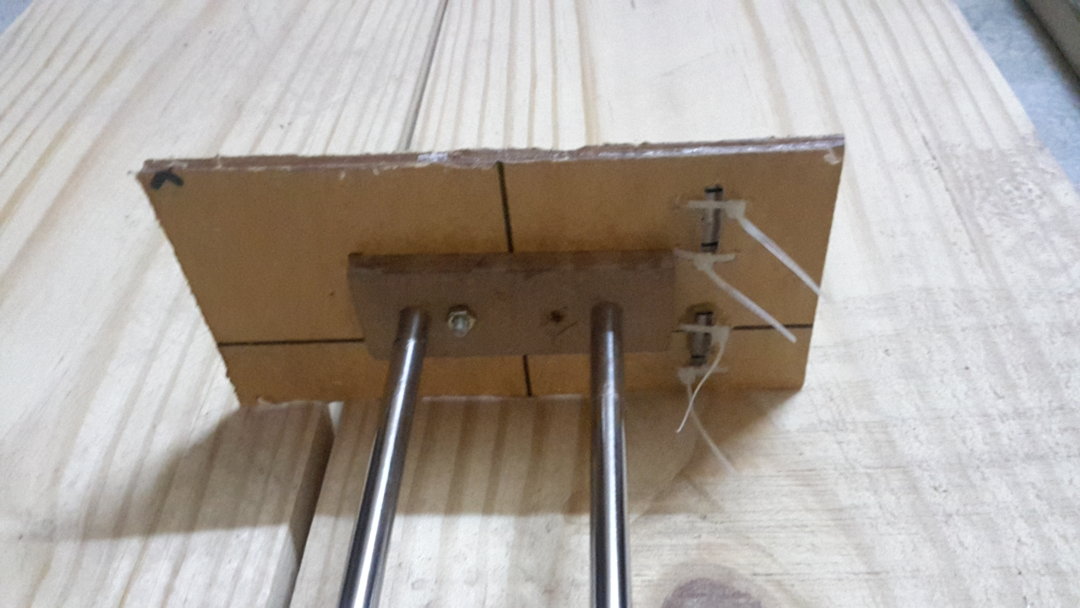

I used 8mm Steel Rods and LM8UU linear bearings for the linear motion. You will get a good glimpse of body with following images:

Conclusion

The build test was very cool as you can see in video attached. The movement is also smooth and fast. Overall weight is also very lite.

To Do

Mount a 3500mw blue laser module.

CNC Laser

Build in 'Laser Cutter Builds' published by Karan Singh Sisodia, Oct 25, 2017.

CoreXY based CNC Laser machine.

-

-

-

- Build Progress:

-

- Build in Progress...

mikememmi likes this. -

-

Build Author Karan Singh Sisodia, Find all builds by Karan Singh Sisodia

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

-

Attached Files:

-

![[IMG]](proxy.php?image=http%3A%2F%2Fcorexy.org%2Freference.png&hash=f951c71c5b2587df324e74bf44528f2c)