The C-Beam Evolution MkII is just a step on the path to the MkIII but I hope to re-use many of the parts.

The MkI machine was a bit of a lash-up made with a fixed C-Beam X gantry and a moving bed Y-axis with no attempt to tidy up the wiring. The Z-axis was a second hand Marchant Dice 75mm travel linear actuator acquired off eBay at a reasonable price. The moving bed Y-axis was again an Ebay acquisition and probably came out of some industrial machine as it had a linear bearing and was belt driven by a NEMA 17 motor. It's main limitation was the bed size (200mm x 200mm) and the fact there was some flex in the assembly which resulted in the MKII plates having slightly oval holes - but easily fixed with a bench drill! The spindle was a rather small 12V 100W Proxxon drill in a 20mm mount. The electrical side was driven by the excellent GRBL (0.9j) running on Arduino with a Protoneer(V3.51)/A4988 shield and Nema 23 motors on the X and Z axes.

I used the MkI for about 3 months while I tried out various software packages and experimented with the capabilities of the machine. I used it to make a number of single and double sided printed circuit boards (KiCAD -> Flatcam -> bCNC), wood and slate engraving (Scorchworks f-engrave) as well as various experimental plates out of thin aluminium, acrylic and polycarbonate sheet designed with SketchuCAM.

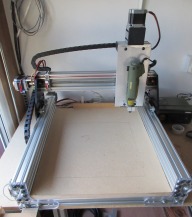

The C-Beam Evolution MkII re-uses the MkI gantry and Marchant Dice Z-axis but mounts it on moving plates on C-Beams driven with separate motors similar to the Kyo's C-Beam Sphinx. The plates are made with 8mm acrylic sheet and the C-Beam is mounted the other way round (lead screw to the front) as the Z-axis is currently connected to the C-Beam using a standard Openbuilds V-slot gantry plate and just 4 wheels. This will get upgraded on the next version when I can make the gantry plates.

The other deviation from the Sphinx is the frame under the C-Beams is made from standard 40 Series aluminium profiles left over from building my CNC bench bolted together with cast corner brackets. Consequently the plates made out of 6mm polycarbonate that support the Y-axis lead screws are customised for bolting on the sub-frame. The MkII build is complete and working but I've already acquired various parts ready to upgrade to more powerful stepper motor drivers and spindle motor. On to the MkIII!

C-Beam Evolution MkII

Build in 'Cartesian Style CNC' published by mikev, May 12, 2017.

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

-

-

-

- Build Progress:

-

- Build Complete!

said01, Vasileios, Pavlov and 1 other person like this. -

-

Build Author mikev, Find all builds by mikev

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

Having spent my career in telecommunications (now retired) I'm used to continuous learning so thought designing and building a CNC machine would be a good project to keep the grey cells active.Inspired by

C-Beam Plate Maker and Kyo's Sphinx -

Attached Files:

-