This delta build will be documented as I go. I am taking a new approach to my building style with this project and designing on the fly for each component. This project will take a little longer this way but can allow for design solutions that would have other wise been over looked with a CAD only upfront design.

This should be a fun build. Join along as I build my large format Delta.

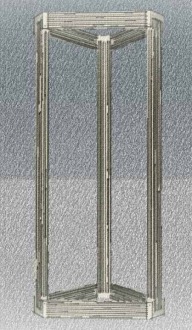

--Frame Details--

Vertical C-beam: 1500mm

Horizontal C-beam: 500mm

Column center to center width: 635mm

Total delta printer height: 1580mm

--Electronics--

Nema 23 x,y,z (α , β , γ)

Nema 17 Extruder

E3D V6 / Volcano Hotend

Smoothie V1.1 Board

The frame as pictured currently sports six different vertex designs I completed some time last year. After printing and testing each I have decided on the vertex design that will work best for this build.

Now I have to print all six. The prototype corners each take around 14hrs to print with a low infill (84hrs total) printing them with a higher infill will take me a little over a week. I plan to start printing them when my petg order arrives. Currently I am prototyping in pla.

Frame design complete, Printing corner vertex files now. Now on to motor mounts and carriage design.

C-beam Delta Printer

Build in 'Delta Bots' published by Kyo, Feb 20, 2017.

Large scale delta robot using c-beam as the core frame component.

-

-

-

- Build Progress:

-

- Build in Progress...

Lumatic, OldFireball and Mark Carew like this. -

-

Build Author Kyo, Find all builds by Kyo

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - No Derivs - CC BY NC ND

Reason for this Build

I have a few custom designs that would be very cost prohibitive to prototype with traditional methods. 3D Printing the prototypes will allow quick iterations before final production. Due to how delta printers scale, it is the ideal choice for this project requiring a large build volume.