It's time to stop dreaming. Let's built it for real.

Specifications

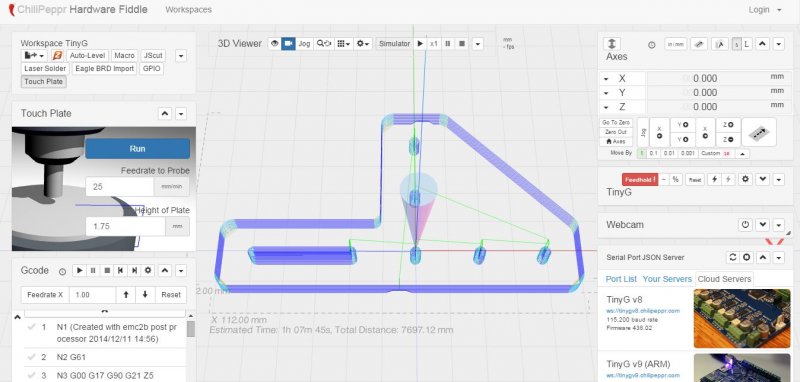

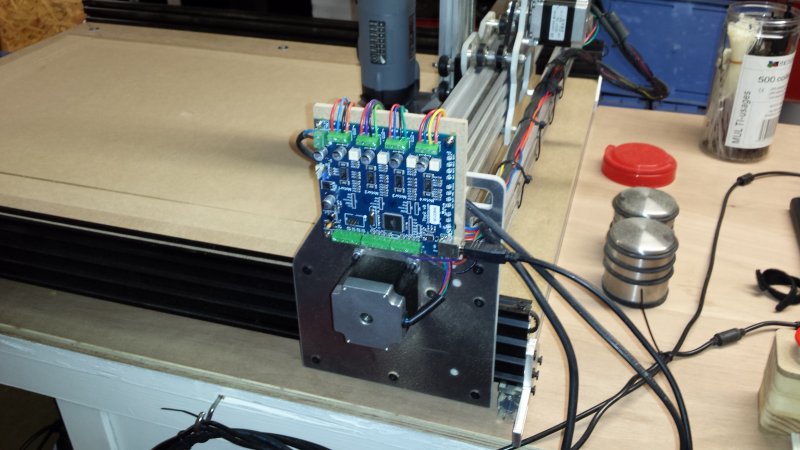

Driver: tinyG - https://github.com/synthetos/TinyG/wiki

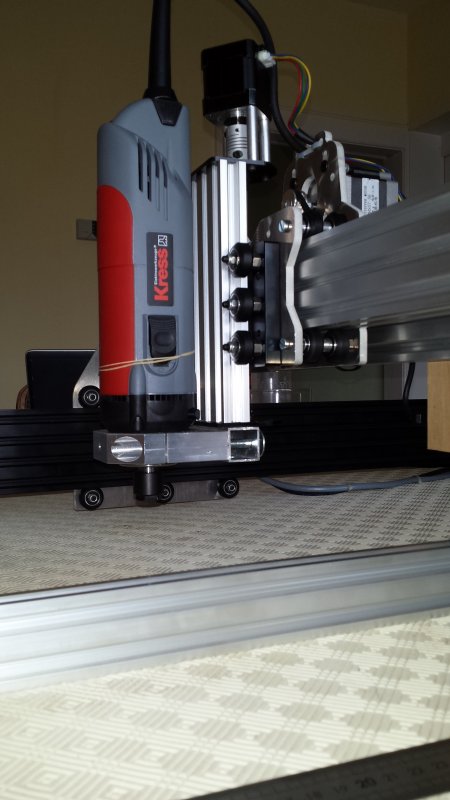

Router: Kress 1050 FM-1 (I took this one because of the slower RPM. Should be easier for plastic)

Software: http://chilipeppr.com/tinyg

Software chain

Design

My mind is just not done the right way when it comes to create something with Sketchup. I create my model with FreeCAD. Great parametric software. I exports the parts in .step. I also made some test with inkscape, especially text engraving, but for the moment, I didn't do it properly

Production preparation

After multiple tests, I finally choose HeeksCNC v1.0.

CNC DrivingI use chilipeppr. Really happy with it. Took me some time to tune the gcode / buffering, but I think the default parameter are OK after all. Very active development.

Hardware buid

OX videos are the basis of this build.

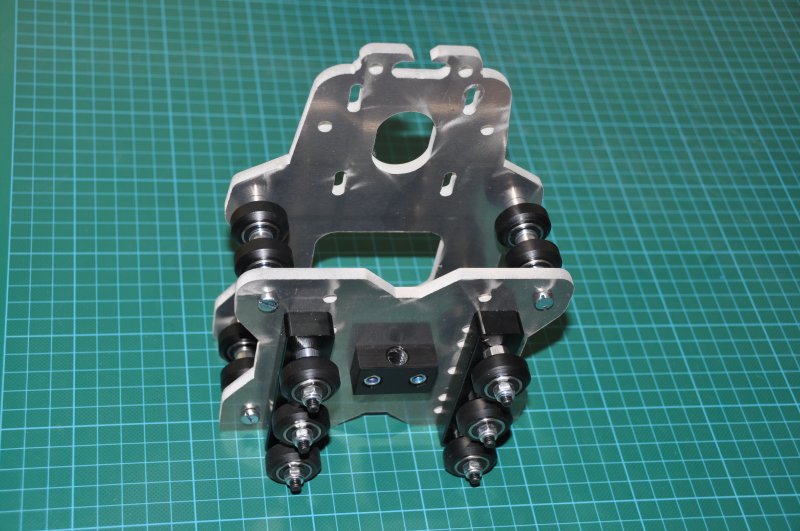

Plate were produced with water cut. The finished of it is not as precise as with mill or laser I suppose. I had to drill some holes again. And of course no engraving...

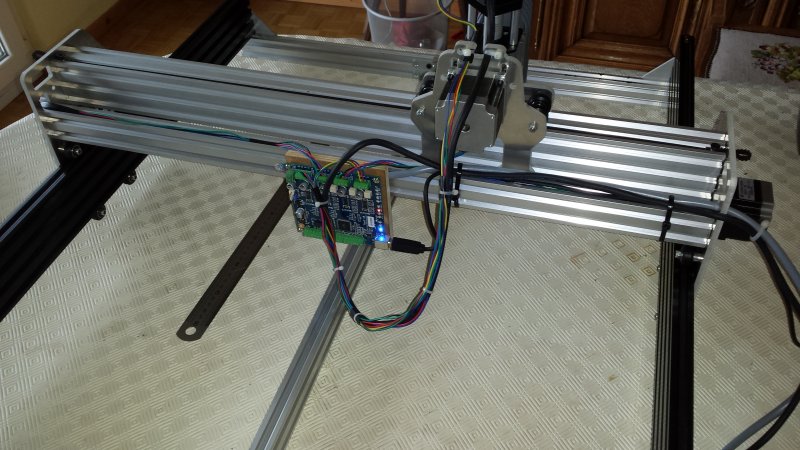

First driver attachment. See the MOD section for current one. Space between driver card and table could be an issue.

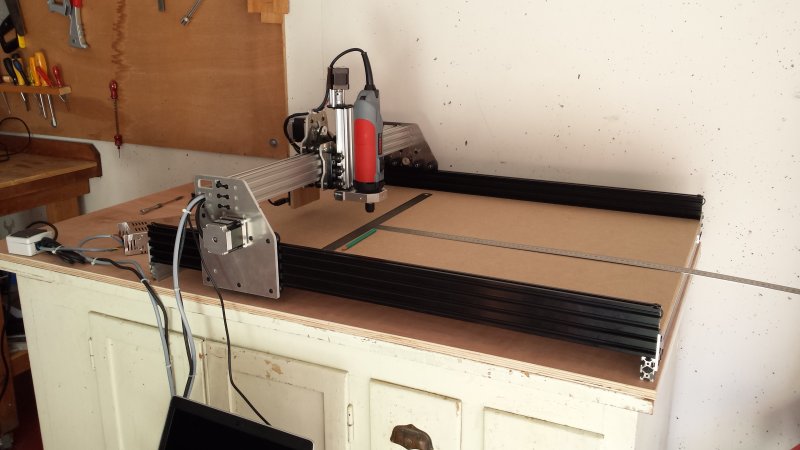

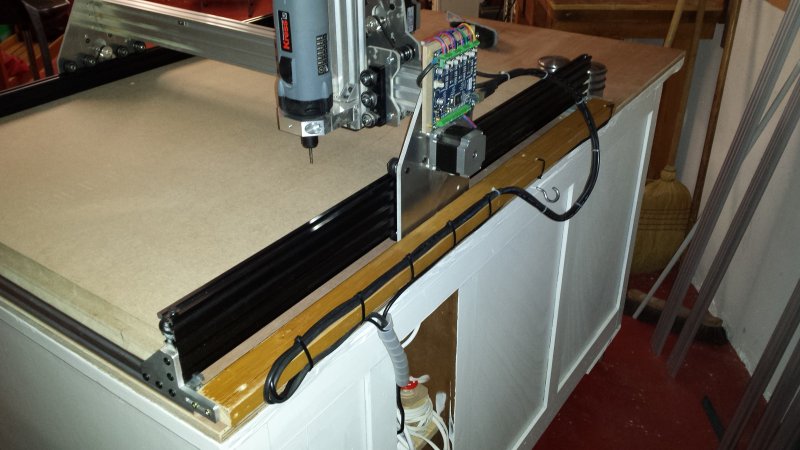

In situation on top of an old commode. This piece of wood was a kitchen between WWI and WWII...

First attempt to attach the mill. This worked, but the clear space between the mill and the table was too low. See the MOD section for current version.

Finished build overview. My daughter made the painting job.

MOD : Emergency stop

I have created an emergency stop with the CNC. Very useful.

Idea was taken from this video

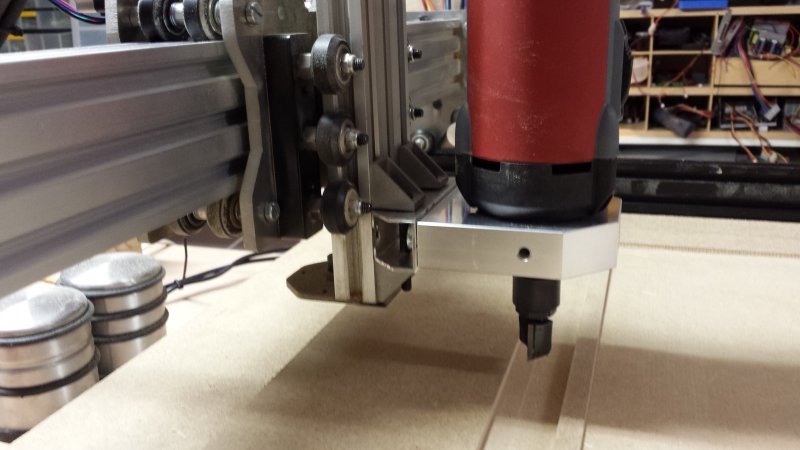

MOD : New mill & driver attachment

During this modification, I noticed that there was an electrical continuity between the hole you see and the borer. I will use this if I add limit switches. I also noticed the 3D printed support from an other build http://www.openbuilds.com/builds/r-ox-cnc-fr-en.1584/. Maybe if I have a 3D printer I will do something like that because on my attachment, the drill is too far from the Z axis.

MOD : Cable path support.

This is my first aluminium cut.

The recycled wood part is a little cheap, but it does the job. Maybe I will replace it with an aluminium rail, and add an echain on it.

Improvement ideas

- I would like to cut DEPRON to build indoor RC planes. A depression table is a must to do something proper. My first attempt to extrude a MDF plate and add tubes to a vacuum cleaner was not good. The 20 mm thick plate bent...

- Maybe a dedicated control station base on a raspberry PI will be added.

- e chain for X & Y axis

- limit switches

bOX

Build in 'Cartesian Style CNC' published by Pendragon, Feb 15, 2015.

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

barmaley and Mark Carew like this. -

-

Build Author Pendragon, Find all builds by Pendragon

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Inspired by

OX, OX AI