I began the planning stages stages in December 2018, as I knew it will be months before the space in my cellar is ready to begin the build. Need to repoint granite block. pour foundation footings under existing granite walls, and pour the rest of the floor.

Meanwhile, I'm Working on the design for the Boss in my spare time.

I decided on a Water cooled spindle because of the lower sound level, and the speed control it achieves. Besides they look real sweet! I'm going over the top on cooling the spindle. I plan to have a radiator to cool the water with flow and temperature monitoring, as well as variable speed temperature controlled fans. These three fans will also pull air through the electronics cabinet. One will run whenever the VFD is in Run mode, another will activate based upon coolant temperature, the third will operate based upon electronic cabinet temperature.

I have spent an unbelievable amount of time trying to research and interpret the chenglish manual that comes with the VFD. I spent weeks reviewing the manual I found online, thought i was done, but when the VFD arrived, it came with a slightly different manual and some setting were different, so i'm going back through it all again. I'll post the spreadsheet that contains my settings and notes.

For the wiring, I'll be going all out as well. Many have used unshielded wire with success, but I have also read comments where machines do unexplainable things in the middle of a cut. Cross talk between control and motor wiring could be the cause but would be very difficult to troubleshoot. The 400Hz spindle will cause a ton of electrical noise, the stepper motors themselves operate at high frequencies and could cause interference. I am going to shield everything to eliminate the possibility of problems.

It is now April 2019 and the cellar upgrade is progressing, I have now ordered all the parts for this build totaling nearly $4000 including software and parts to repair an old PC. Many parts are arriving daily as I finish my design, wiring schematics, work station and other details. also trying to resurrect an old PC that I had on hand to control this beast.

Repairing the old PC was harder than i thought, I had many driver issues and the machine was slow, I re-installed XP but now it is stuck with SP1 and won't connect to the internet. I was gonna use it as is, but in researching options I decided to add a smoothstepper to the build and take a lot of the burden off the old PC to increase the reliability of my setup. I then found a rebuilt PC win win 7 installed on amazon for $135,...Done.

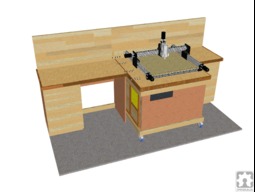

It's May, and the Cellar upgrade is done, I've begun building the cabinets for the Work Bee so I think its time to publish this build. P.S. I keep adding features to the CNC as I wait to build it, plus the lumber for the cabinets, This Build just topped $5000.

Working on the adapter bracket for the spindle, trying to incorporate some tramming adjustment.fullsizeoutput_15b2.jpegfullsizeoutput_15b4.jpeg

Bee the Boss

Build in 'Cartesian Style CNC' published by Stan Howe, Jun 2, 2019.

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

Special Notes

I am concerned with the weight of the spindle and the feedback I have read about the extreme V rollers. Also read that the C beam can flex under load. I will build this machine and if/when rollers or flex becomes an issue, I will use this machine the make the parts required to upgrade to lineal bearings. the inspiration for this comes from Jacob Lotter and his 1510 Workbee Modified. In the meantime, a mechanical engineer friend of mine suggested balancing the weight of the spindle with gear on the back side . I'm going to try that with lead weights. I also thought a couple threaded rod through the gantry couldn't hurt.

-

-

Build Author Stan Howe, Find all builds by Stan Howe

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

I got a Sainsmart 3018 Pro (6" x 11.5" work table) for christmas, it is a nice , but VERY small machine using a slow(7000 RPM) under powered spindle. After the initial learning curve I was hooked on CNC. I love building my own things and modifying them to make it better. After lots of research, thought and planning I have settled on the Work Bee with a 1.5kW water cooled spindle as my next (and last) machine. If I'm gonna upgrade, I will go big the first time and not feel the need to upgrade again because of lack of workspace or power.Inspired by

Workbee 1010, 1510 Workbee Modified