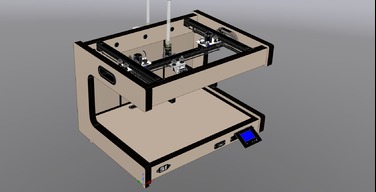

Functional real-world build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks. Plasma cut steel and stainless steel components - several with easy bends. CNC routed Columbia Purebond hardwood plywood and resin components. 2GT belts on OpenBuilds smooth idlers with 688 bearings. 1/2in ACME lead with Delrin anti-backlash nut. NEMA 17 on X/Y and NEMA 23 for Z. Feeds and acceleration, despite weight in motion, exceed those required for 3D printing. Pictured with temporary wood bed supports, which will be replaced with resin. Build is pretty much complete, except for deciding on a bed and waiting for ordered spring coil to go over the vinyl tube for wire management. Marlin 2.x on SKR v1.1 controller with DRV8825 and TB6600 for Z.

3D Printer 051

Build in 'Cartesian Style Bots' published by xyzzy603, Sep 30, 2020.

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

Special Notes

Torque 3/8in. fasteners (dry) to 24 ft. lb. and 5/16in. to 12 ft. lb. where appropriate.

MkrNBlk and Mark Carew like this. -

-

Build Author xyzzy603, Find all builds by xyzzy603

-

- Loading...

-

Build Details

- Build License:

-

- CC - Creative Commons Public Domain (CCO 1+)

Reason for this Build

Constantly having to replace junk linear motion components on FFCP, D6, and others. Wanted something less fragile, with larger bed, and low maintenance.Inspired by

Lack of maintenance on plasma tables with RM2 bearings. -

Attached Files:

-