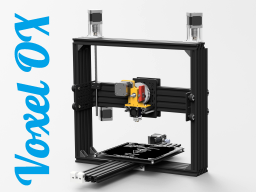

Voxel OX 3D Printer

Discussion in '3D printers' started by Marshall Peck, Sep 27, 2015.

Voxel OX - Extendable 3D Printer and CNC Platform

Discussion in '3D printers' started by Marshall Peck, Sep 27, 2015.

An open source 3D printer design with a sturdy V-Slot frame

Page 6 of 7

Page 6 of 7