As this build is just starting as always this is my best resource for information and ideas so it would be great to get your input along the way.

I am now on my 5th laser cutter and have decided to replace all with my self designed and built hopefully heavy duty and reliable machines.

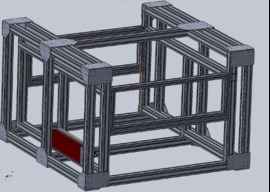

The majority of the framing is made from heavy duty 8080 aluminium extrusion. What are your favorite connections to use on 8040? I like to use double whistle connectors with a gusset plate and in some locations cast aluminium corner brackets. All gusset plates are 6mm or 8mm. Bed size is 1250mm x 1250mm. Laser tube is the always reliable iradion 250W ceramic tube, Motors are servos, currently the controller is a Ruida ESP however this may change before completion, I have only ever used Trotec or Ruida, is there a better option? I had designed this with 30mm belts on the X axis but it would be great to hear experiences some of you may have had with gear racks and ball screws on a laser (to better keep up with a high mm/s capable servo setup) Previously I have used Hiwin rails and a separate belt but a sealed rail linear module might be the better way to go.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Build in 'Laser Cutter Builds' published by Ollieg, May 6, 2019.

Starting the next Laser build, Plan to complete within 60 days.

-

-

-

- Build Progress:

-

- Build in Progress...

Tobias Fletcher and Nathan Horsley like this. -

-

Build Author Ollieg, Find all builds by Ollieg

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

A more reliable and quicker machine