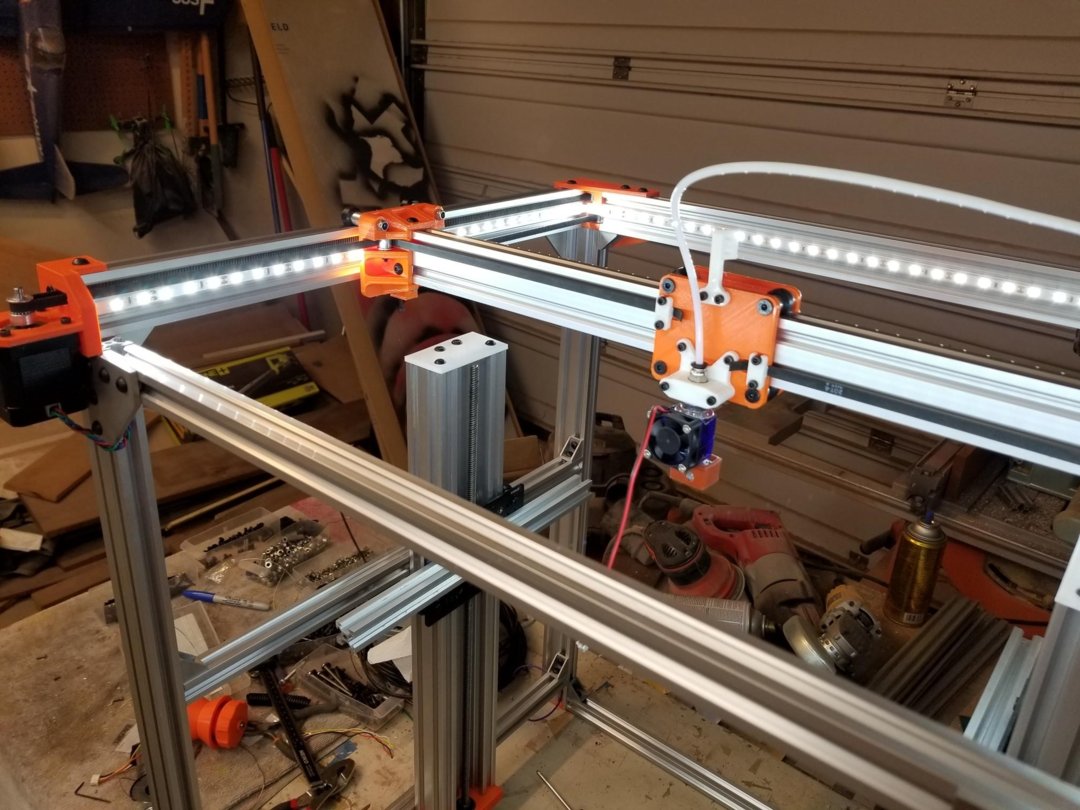

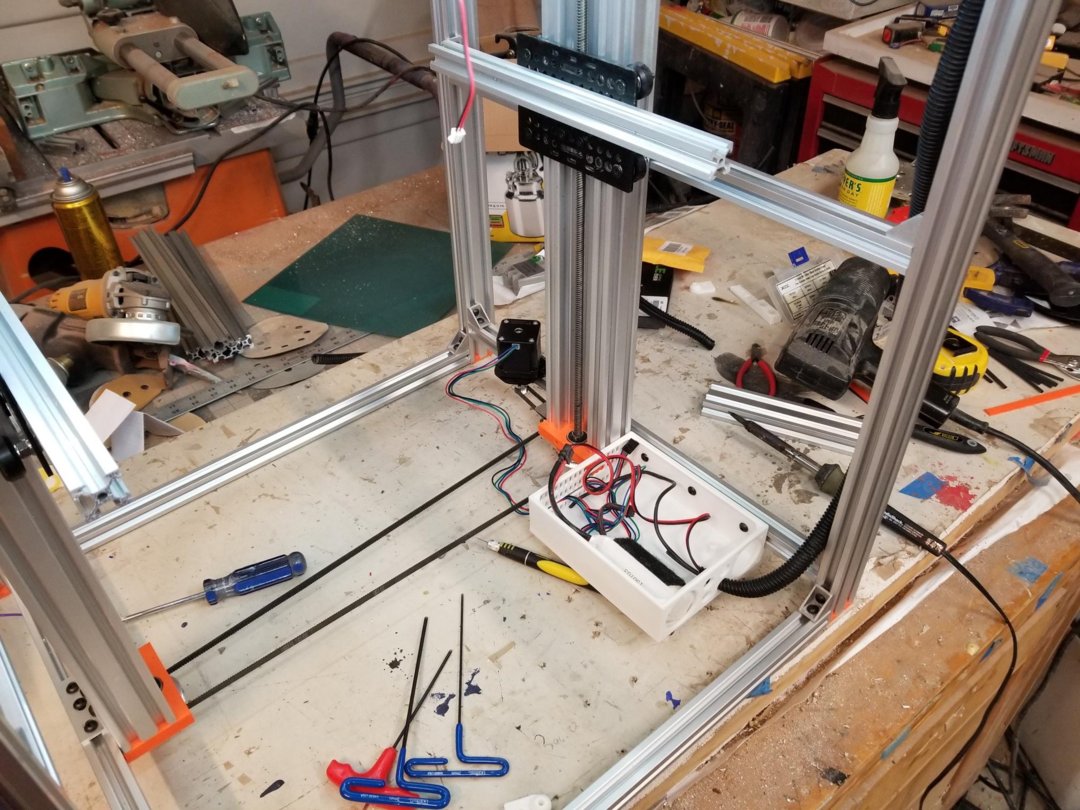

I ended up using as much metal bracing as possible instead of the 3d printed parts (All printed parts were made with PETG). This is a major upgrade in the Z-axis by adding C-Beam and using larger plates. This uses a single Nema 17 to drive the Z by incorporating 3:1 gear ratio.

Double D-Bot 400mm x 400mm x 600mm

Build in 'H-Bot and Core XY' published by Troy Proffitt, Feb 11, 2019.

Based on D-Bot but used more metal bracing / openbuild plates instead of plastic parts. Also size was increased.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Justin3968, Gaberiel_1972, boncalo and 26 others like this. -

-

Build Author Troy Proffitt, Find all builds by Troy Proffitt

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

Started with a smaller basic Prussia I3 printer, but quickly realized I needed something larger. Really liked the D-bot designInspired by

D-Bot