Thought that I'd take a few minutes and share some pictures and thoughts on building my OX variant.

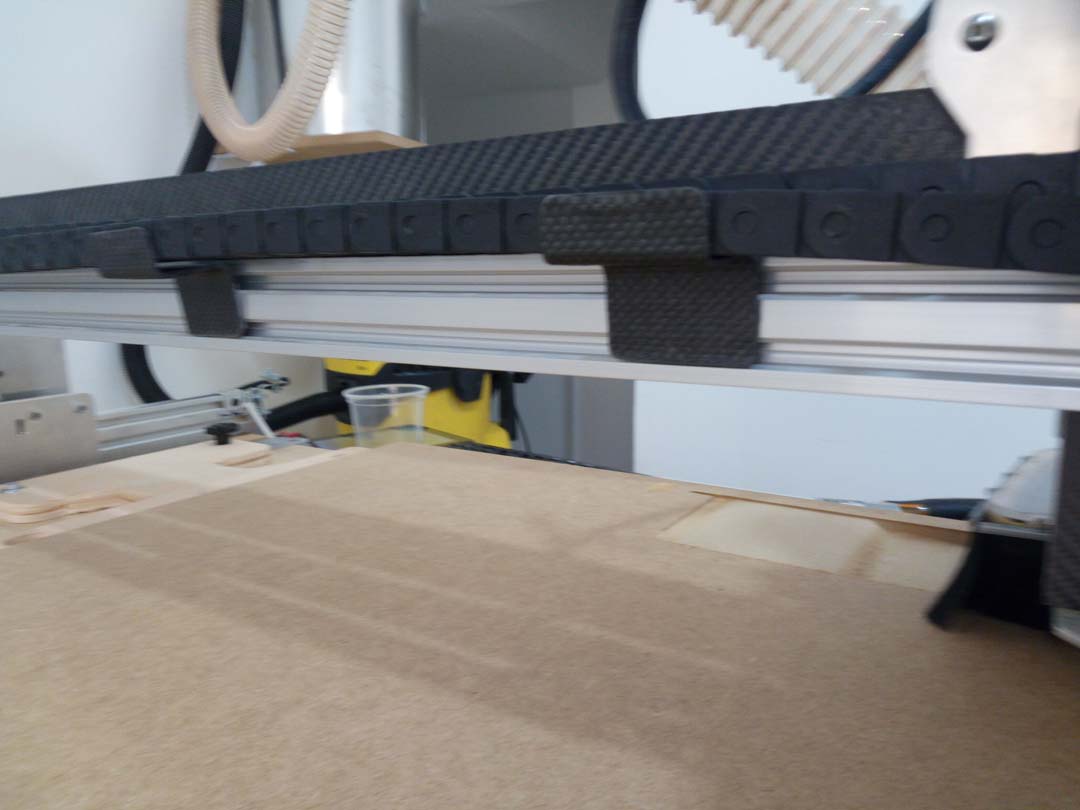

I wanted a machine for mainly making cheap one off molds for composites. Being able to machine 50mm blue or pink foam was important to me so my machine has a extra tall Z axis. All the plates were machined by Chris Laidlaw who did an awesome job. The Y axis plates are taller and have a modified hole pattern because of the 3 pieces of 3mm carbon plate that are bonded together with the X axis extrusions. The corner pieces were a custom design to incorporate the home/limit switches.

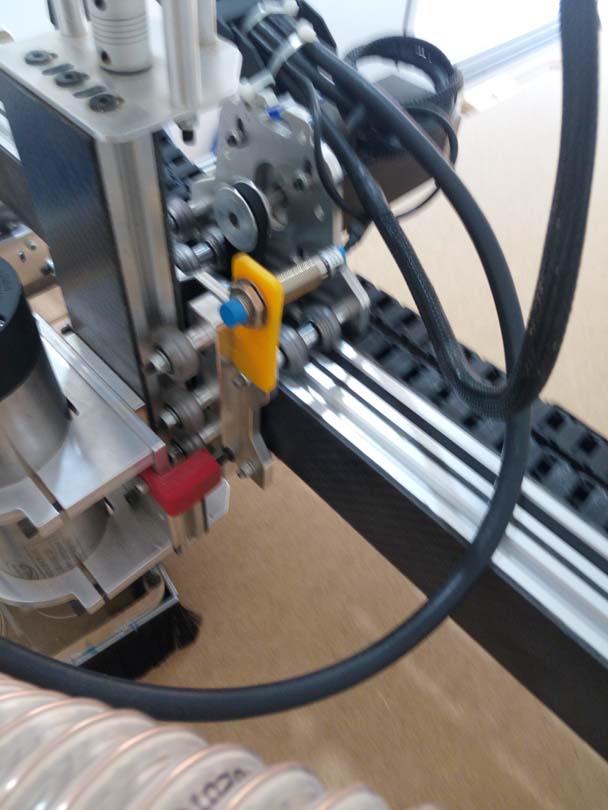

It has double belts and I had a number of issues with them though I think I've reached a good solution. Originally I used double sided tape to hold the bottom belt in place though I found that there was too much space between the two belts for proper engagement, also I had a real issue with getting the tension of the two belts to match. Next I tried using a double sided tape with foam in order to raise the lower belt. This definitely improved the function of the printer but came with a price. Eventually the lower belt moved to one side in the extrusion slot and the top belt would slip to the other side and be under the lip of the slot. While this meant that the belts were very well engaged as the carriage would move it would pull the top belt out of the slot along the edge of the slot and tear it apart filling the wheels with rubber debris. I ran this for a while and the machine cut nicely it wasn't really sustainable. Just a few weeks ago I came up with a solution that so far has proven to work quite well. Still double belts but no glue on the bottom and both of them attached to a tensioner. The tensioner is made from some simple 40mm brackets I found at the hardware store and some threaded rod.

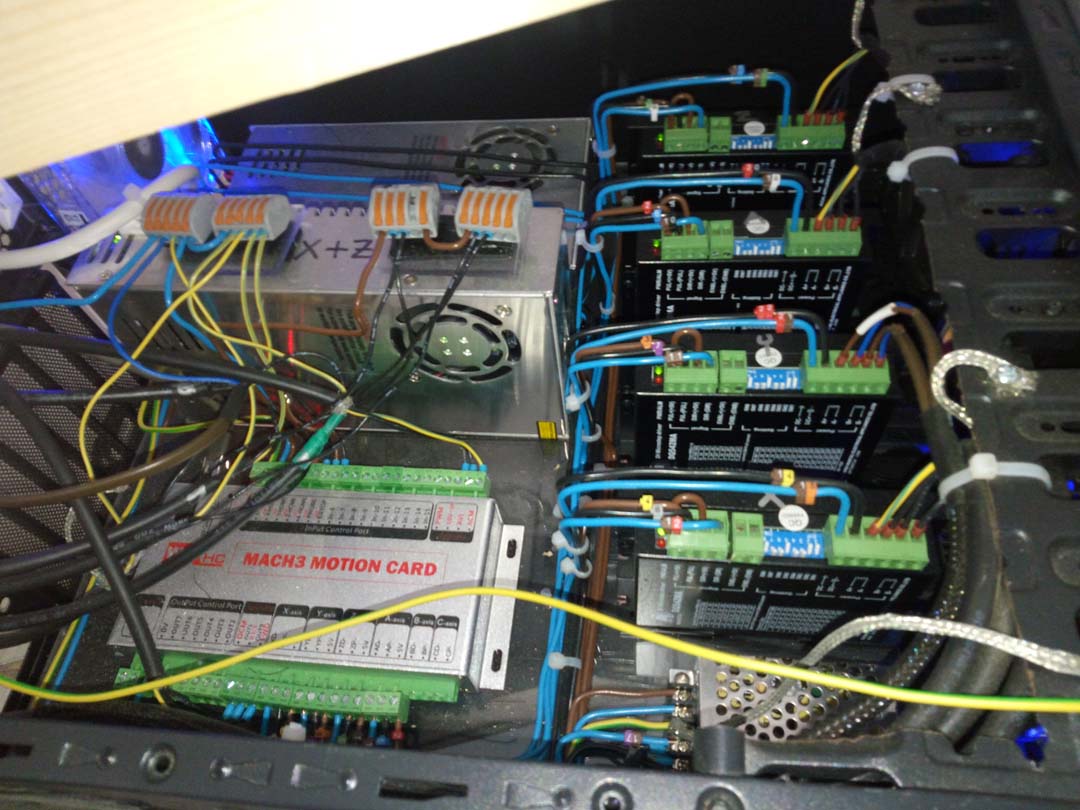

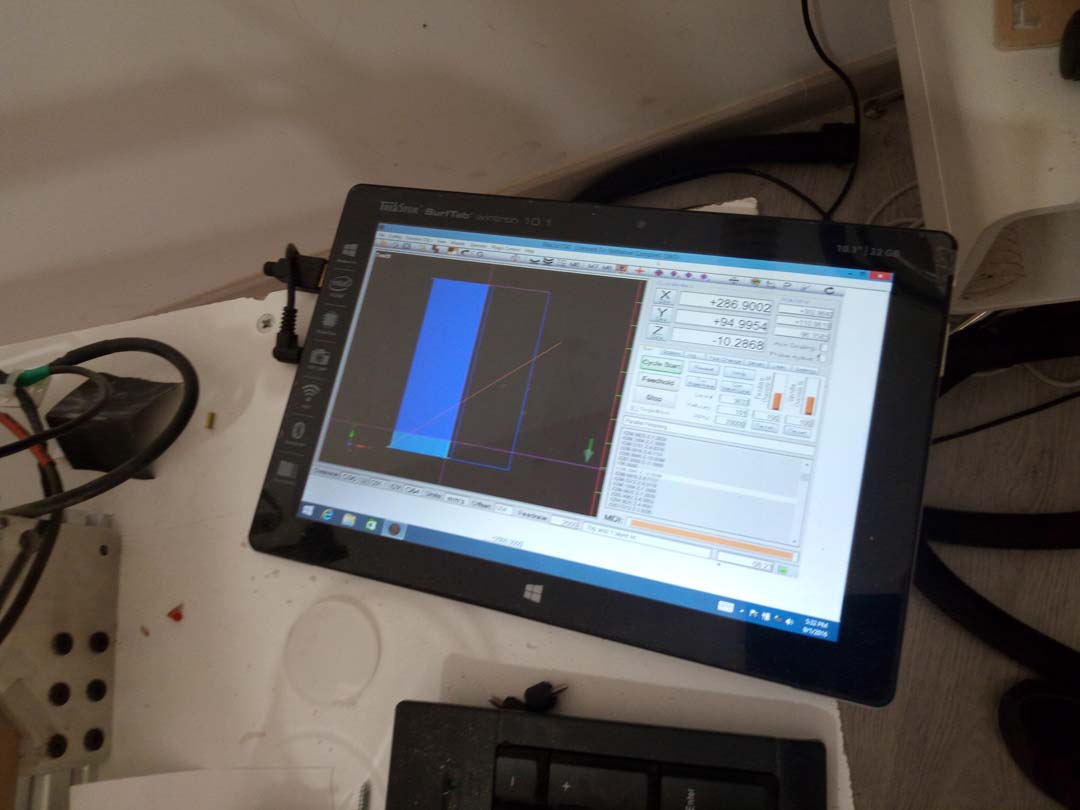

Motors and electronics are all Chinese. I would have loved to buy nicer stuff but it all seems to work. for the motors and drivers I got a Longs set with the large NEMA 23 (425 oz/in) motors. Over kill for this machine but if I ever have the space to make a bigger machine they will slot right in. For the controller I got a WiXHC USB mach 3 controller. I didn't want to spend the time hunting down a computer with a parallel port and wanted USB connectivity. While it's not perfect it has seemed to work well. The only thing I haven't gotten working is speed control. I also got a 1.5 kW air cooled spindle with VFD I haven't had and issues with it other than not checking the rotation when I first put the machine together. Not sure where I read it but a great tip for this is to put a piece of masking tape on the spindle so you can see the direction of rotation. I built out the electronics in a PC case which was around 50 euros as a real enclosure can be really expensive. I also added a small 12v power supply to run the cooling fans, endstops and controller. For software I'm running Mach 3 on a cheap tablet.

For dust extraction I'm running a cheap plastic cyclone that I installed in a small container hooked up to my shop vac. Not ideal and a bit loud but it seems to work well. I made the dust shoe and originally it was just a piece of plywood with a door sweep on it. I finally got tired of having trouble seeing what was happening and tool changes and cut a acrylic top and glue a bunch of magnets to it. I just cut out the middle of the plywood dust shoe and the magnets attach to the metal rail of the brush. a bit ugly but definitely an upgrade

So far it has mostly been used for making toys and furniture for my 1 year old son. Once my wife figured out what it could do I have had a constant stream of requests...

![IMG_20160904_082156[1].jpg](https://openbuilds.com/attachments/img_20160904_082156-1-jpg.19104/)

Finish off with a few more random pictures. If you have any questions feel free to ask

CrOX Carbon Reinforced OX

Build in 'Cartesian Style CNC' published by nate campbell, Sep 4, 2016.

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

-

-

-

- Build Progress:

-

- Build Complete!

-

-

Build Author nate campbell, Find all builds by nate campbell

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY