YAOR (Yet Another Openbuilds Router)

Discussion in 'CNC Mills/Routers' started by winand, May 30, 2014.

YAOR (Yet Another Openbuilds Router)

Discussion in 'CNC Mills/Routers' started by winand, May 30, 2014.

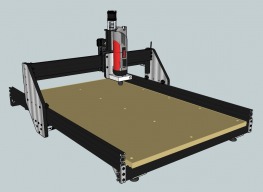

Yet Another Openbuilds Router, my version :-)

Page 2 of 2

Page 2 of 2