SOLAC: Space Optimized LAser Cutter

Discussion in 'Laser Cutters' started by Lumberjack Engineering, Feb 18, 2017.

SOLAC: Space Optimized LAser Cutter

Discussion in 'Laser Cutters' started by Lumberjack Engineering, Feb 18, 2017.

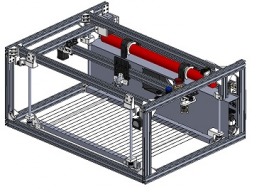

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Page 2 of 2

Page 2 of 2