KYO SPHINX a la' SCYBUCK

Discussion in 'CNC Mills/Routers' started by SCYBUCK, Oct 16, 2018.

KYO SPHINX a la' SCYBUCK

Discussion in 'CNC Mills/Routers' started by SCYBUCK, Oct 16, 2018.

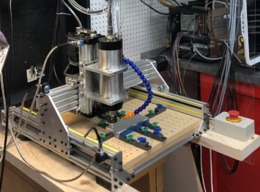

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Page 2 of 2

Page 2 of 2