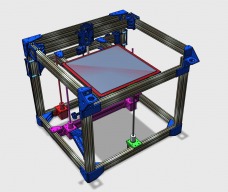

C-Bot

Discussion in '3D printers' started by Carl Feniak, Sep 29, 2014.

C-Bot

Discussion in '3D printers' started by Carl Feniak, Sep 29, 2014.

A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy.

Page 26 of 107

Page 26 of 107