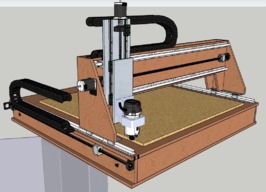

Plywood Built CNC Router

Discussion in 'CNC Mills/Routers' started by Project Hopeless, Aug 19, 2019.

Plywood Built CNC Router

Discussion in 'CNC Mills/Routers' started by Project Hopeless, Aug 19, 2019.

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.