Fixed Gantry Welded Steel Router

Discussion in 'CNC Mills/Routers' started by Matt Barile, Mar 22, 2017.

Fixed Gantry Welded Steel Router

Discussion in 'CNC Mills/Routers' started by Matt Barile, Mar 22, 2017.

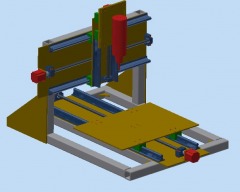

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress