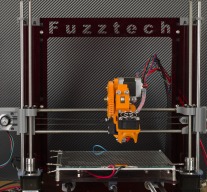

Prusa i3 (Acrylic frame with OB rods)

Discussion in '3D printers' started by dddman, Feb 6, 2015.

Prusa i3 (Acrylic frame with OB rods)

Discussion in '3D printers' started by dddman, Feb 6, 2015.

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

Page 4 of 6

Page 4 of 6