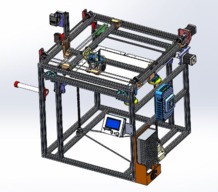

Dash-X 3D Printer: Innovative design

Discussion in '3D printers' started by Neil Rosenberg, May 21, 2019.

Dash-X 3D Printer: Innovative design

Discussion in '3D printers' started by Neil Rosenberg, May 21, 2019.

Cross-beam Cartesian 3d printer with dual master/slave lightweight fiberglass drive shafts, BMG style extruder with Bowden (Capricorn) tubing. Hot end is Creality Ender 3 style with two fans and BLTouch for autoleveling. Filament runout sensor is also included.

Page 4 of 4

Page 4 of 4