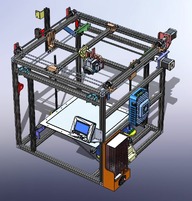

Dash X Direct, Cross-Beam 3d Printer

Discussion in '3D printers' started by Neil Rosenberg, Mar 29, 2022.

Dash X Direct, Cross-Beam 3d Printer

Discussion in '3D printers' started by Neil Rosenberg, Mar 29, 2022.

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr