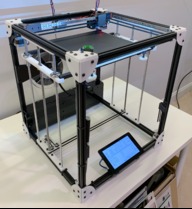

GridBot Two

Discussion in '3D printers' started by SOA, Jan 26, 2020.

GridBot Two: Powerfully Simple

Discussion in '3D printers' started by SOA, Jan 26, 2020.

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

Page 1 of 4

Page 1 of 4