Lautr3k

Discussion in '3D printers' started by skarab, Jan 7, 2014.

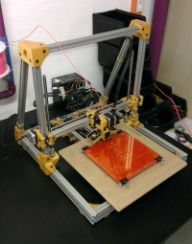

Lautr3k RepRap

Discussion in '3D printers' started by skarab, Jan 7, 2014.

A 3D printer without belts, a print volume of 320x320x260mm, obviously the V-Slot as linear guide! and a maximum of printed pieces.

Page 9 of 17

Page 9 of 17